This video contains proprietary information and cannot be shared publicly at this time.

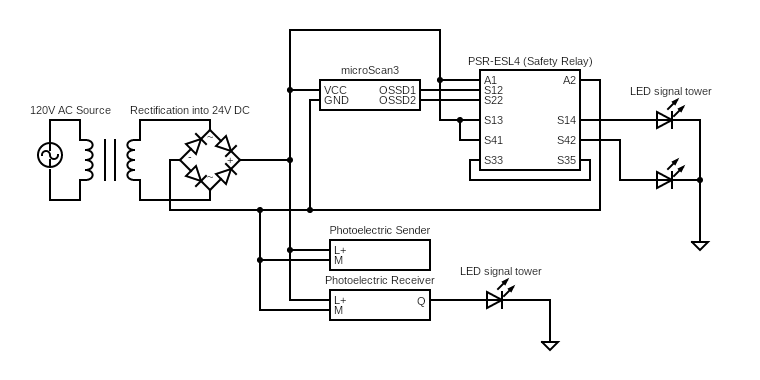

Figure 1

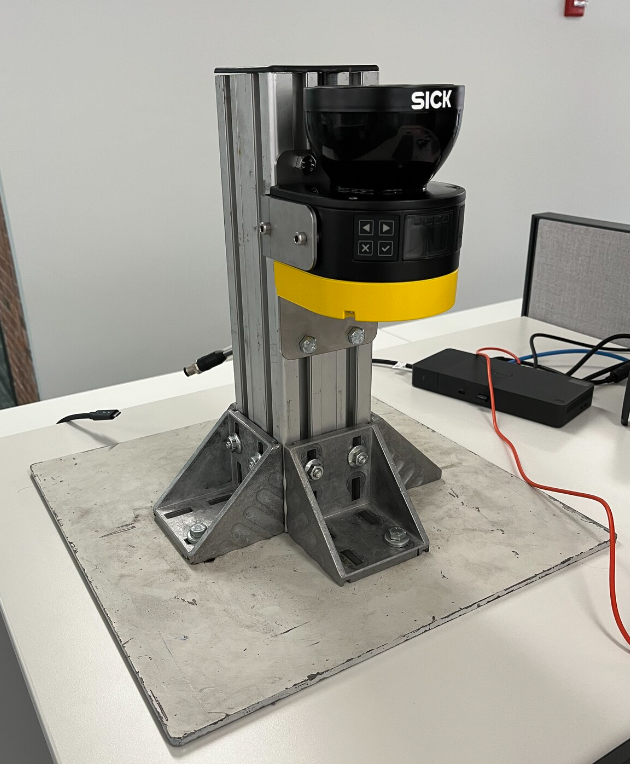

Figure 2

Team 09

Team Members |

Faculty Advisor |

Haseeb Mahmood |

Ashwin Dani/Liang Zhang Sponsor TRUMPF |

sponsored by

Detection of People and Material in Machine Automation Environment

Trumpf is a manufacturer of fabricating equipment and industrial lasers with its headquarters based in Ditzingen, Germany. Trumpf provides innovative solutions to their customers in the field of sheet metal processing, laser-based processes, and other related manufacturing areas. Trumpf regards safety as the most critical requirement for all of their automation cells which are used for processing the raw material. The current safety measures employed in the automation cells include fences/gates, light barriers, and light curtains. The objective of this project is to elevate the quality and safety standards of one of their automation cells. Operator safety is the primary focus of the safety detection system while detecting misaligned material in the automation cell is the secondary concern. The initial phase of the project included research of potential candidates for the detection system sensors. After the potential solutions were identified, a Pugh matrix was utilized to assess the solution that aligns with the safety and flexibility requirements. The design phase of the project focused on the feasibility of different types of sensors integrated into the automation cell such as laser scanners and photoelectric proximity sensors. An ANOVA statistical analysis was performed on the multisampling rate of the laser scanner to recommend the optimal response time for the application. The result of this project is a standalone detection system that is ready to be configured to the machine PLC and HMI interface.

Our team collaborated with Mechanical Engineering 58 on this project.