This video contains proprietary information and cannot be shared publicly at this time.

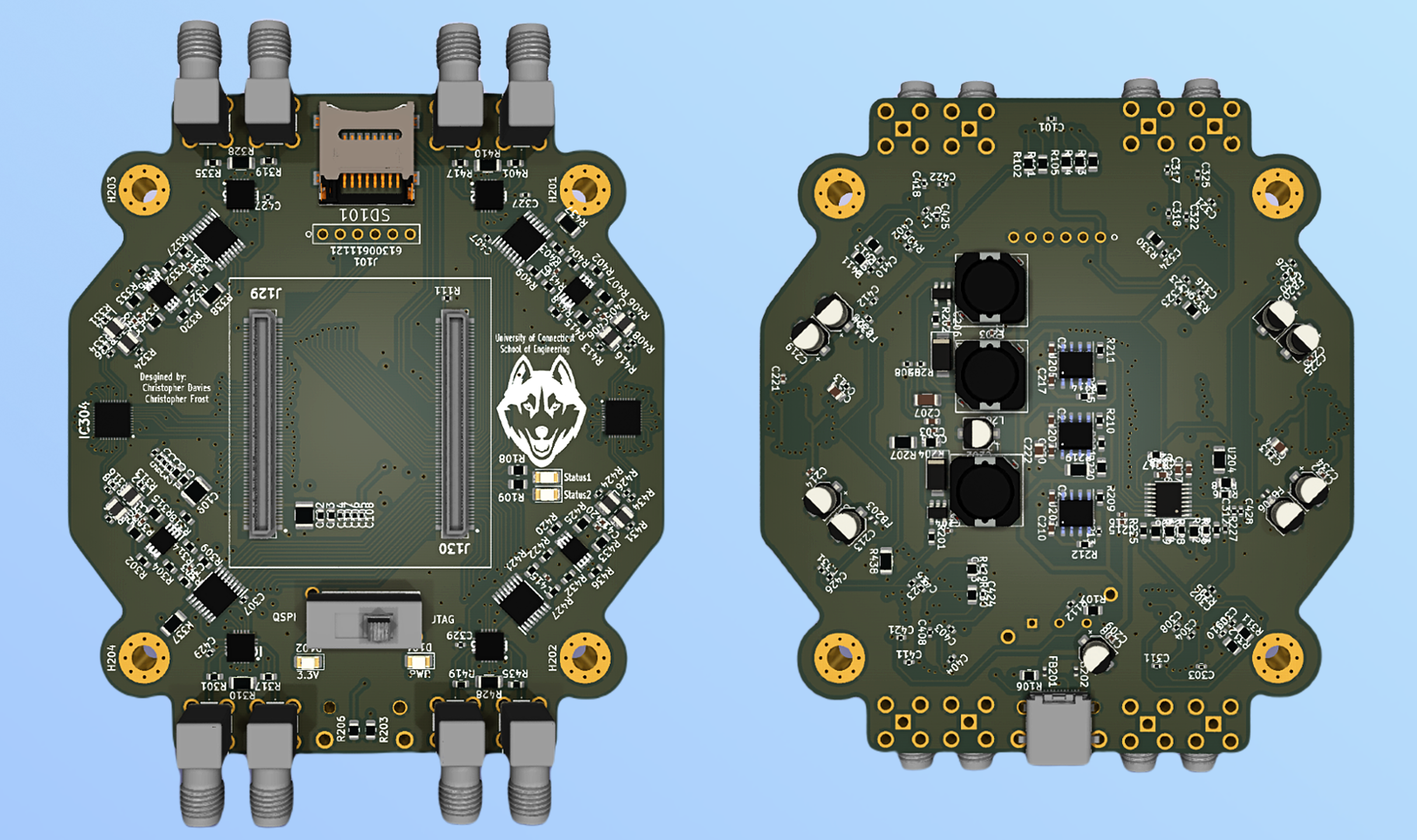

Figure 1

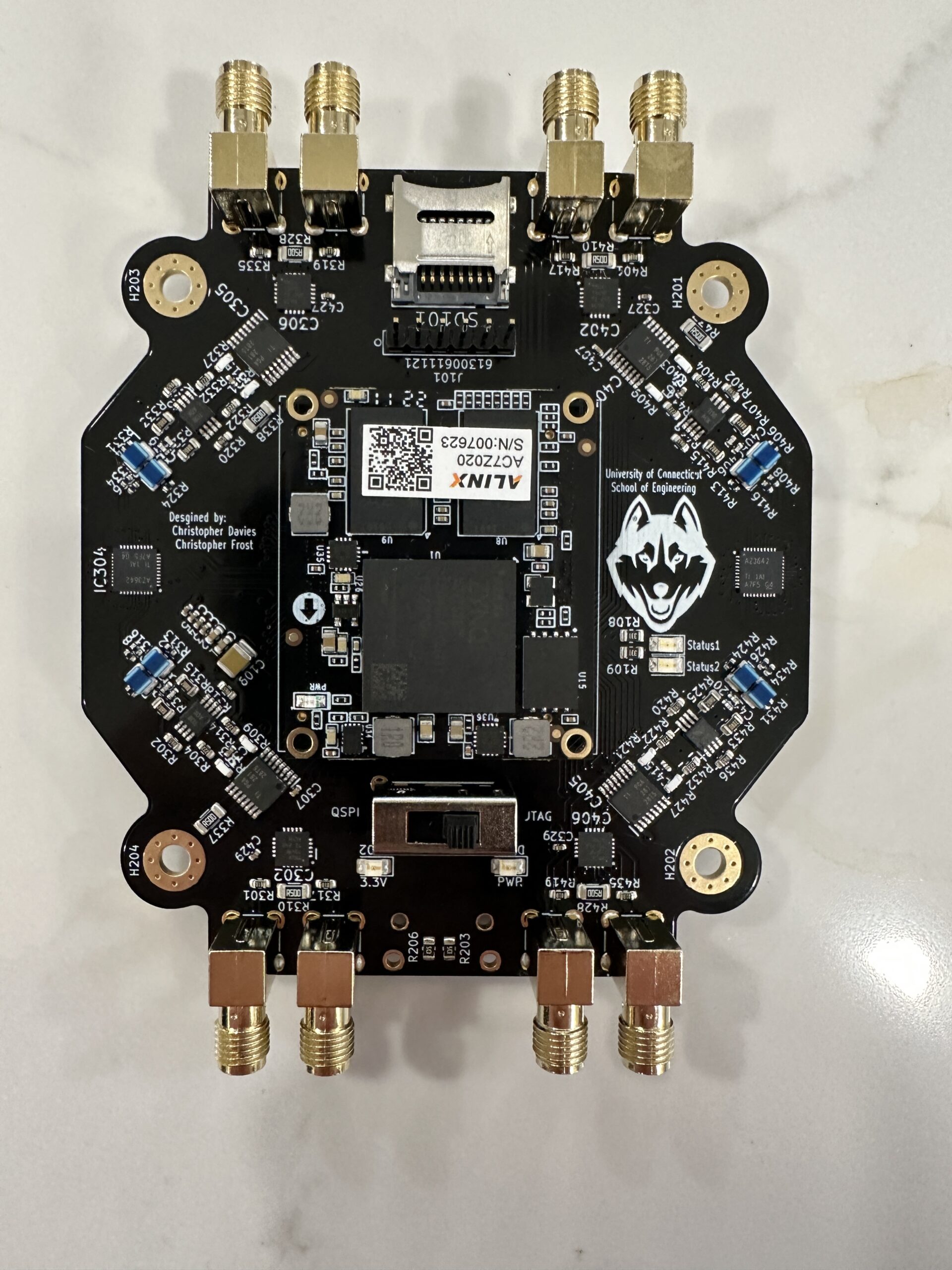

Figure 2

Team 2324

Team Members |

Faculty Advisor |

Christopher Frost |

Dr. Chandy Sponsor Collins Aerospace |

sponsored by

Compact and Robust Data Logger

Collins Aerospace has requested a continuation of last year's project to create a compact and robust data logger that can withstand extreme environmental temperatures. This will be used for testing aircraft parts in simulated real-life settings. The data logger has four channels and each can sample signals of +/- 60V at a frequency of 6 MHz. This is a significant increase to the previous year's project which could sample +/- 15V at 1Mhz. The data logger reads a removable micro SD card to set its programmable trigger. Once this programmable trigger event is met, it will save the following sampled data on the same SD card. The team has done a complete redesign of the previously created device developing a six-layer PCB which quadruples the voltage input range and sextuples the 3dB bandwidth. This is all while reducing the surface area of the PCB from 23 square inches to 11 square inches. The requirements for the circuit board are that it should be compact, be able to sample four differential inputs at 6 MHz frequency, be able to withstand temperatures of -40°C to 85°C, store the digitized version of the signals on a removable storage device, read user input settings, and have status indicators. Our PCB design includes eight SMA connectors for the four differential inputs, each with a very low noise custom analog signal process that has programmable gain, automatic gain correction, and steps down the voltage for a high-performance 25 MSPS ADC. This then interfaces with a Xilinx Zynq FPGA/CPU and a USB-C input to power the onboard voltage regulators. There are also two status indicator lights and a micro SD card slot. This year we also included a switch to set the FPGA to boot from either jtag or our onboard QSPI flash.