This video contains proprietary information and cannot be shared publicly at this time.

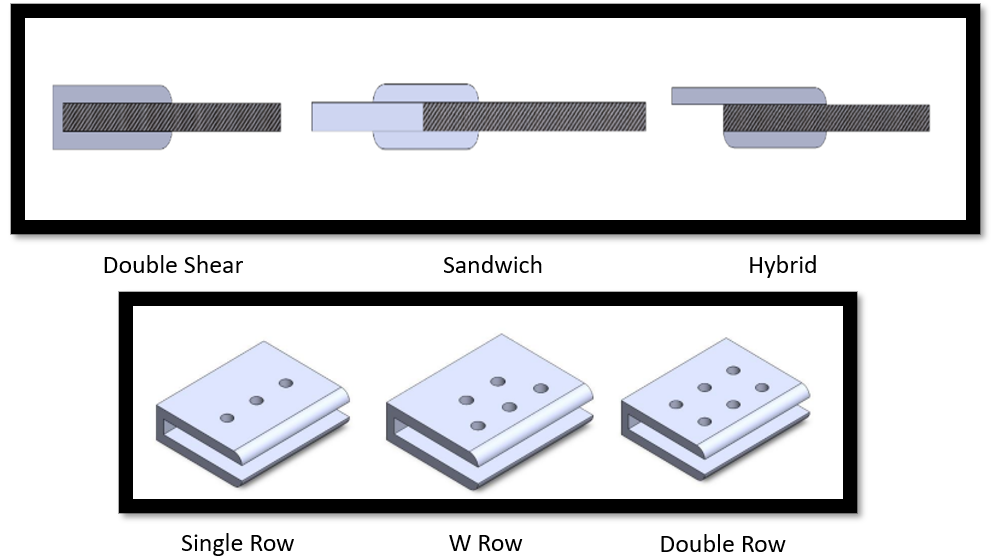

Figure 1

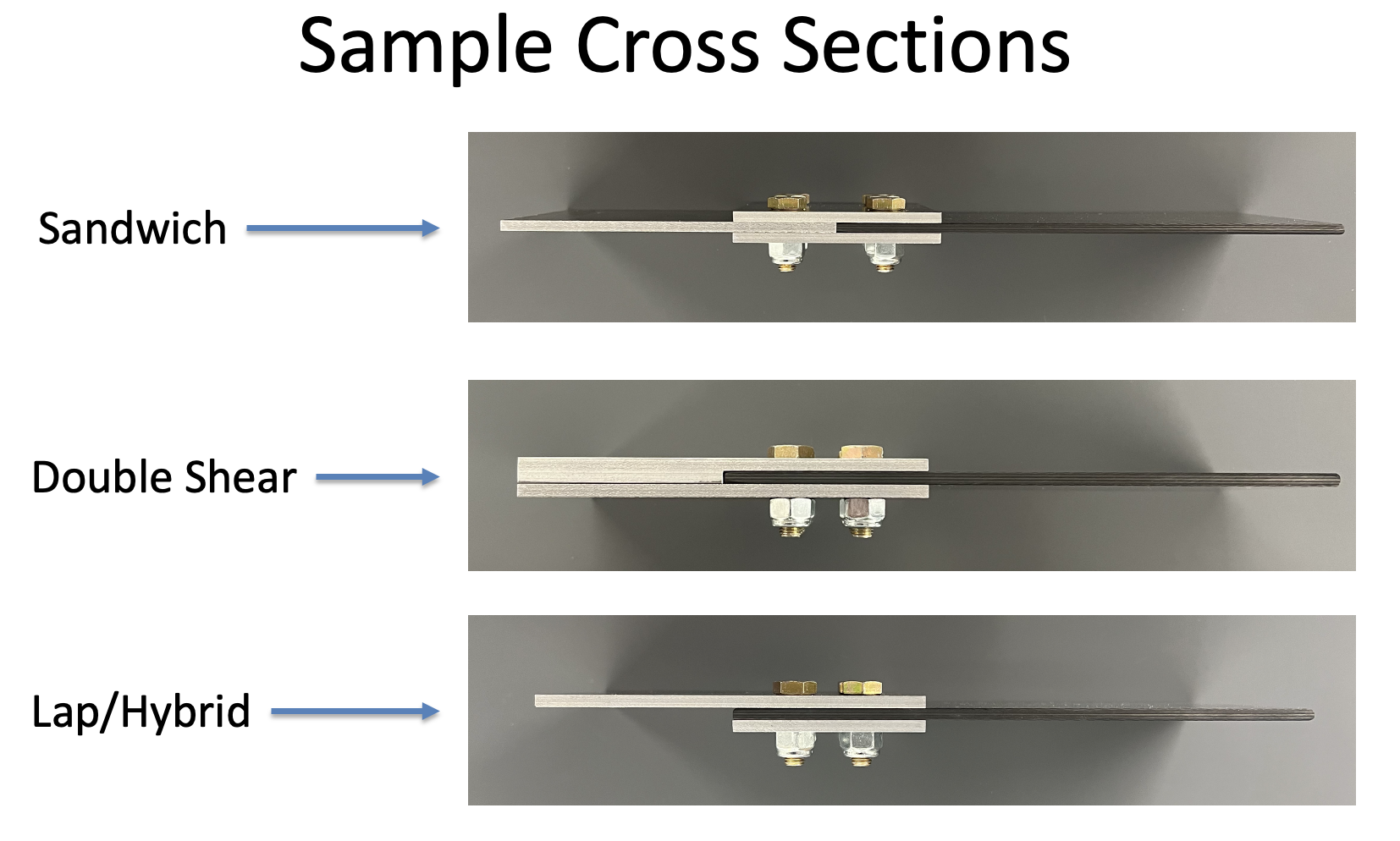

Figure 2

Team 8

Team Members |

Faculty Advisor |

Seth Utter |

Xueju Wang Sponsor Pratt & Whitney |

sponsored by

Hybrid Composite Metal Case Design

Materials science and engineering senior design team eight is working in conjunction with Pratt & Whitney to develop and assess designs which connect metal and composite components for use in next generation gas turbine engine fan cases. These next generation fan cases will be made from lighter and stronger composite materials like carbon fiber reinforced polymers (CFRP), which will replace current heavier metal fan case designs. This material change from metal to CFRP for fan cases will significantly reduce engine weight, subsequently leading to increased engine efficiency and cost performance. To make this material change viable, novel methods of connecting CFRP to metal need to be created and evaluated. The goal of our team is to create three unique interface designs as well as three variations on each base design. Each design variation will simply be a different number and pattern of bolts put into the design. Performance of our interface designs were quantified by two tests: tensile load to failure testing and fatigue cycle testing. Testing data as well as failure analysis data will be collected during and after each test. Data received from both tests will be used to make a recommendation on which joint type is best suited for a fan case application.