This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

Team 4

Team Members |

Faculty Advisor |

Mathes Payne |

Craig Calvert & Rajiv Naik Sponsor GKN Aerospace |

sponsored by

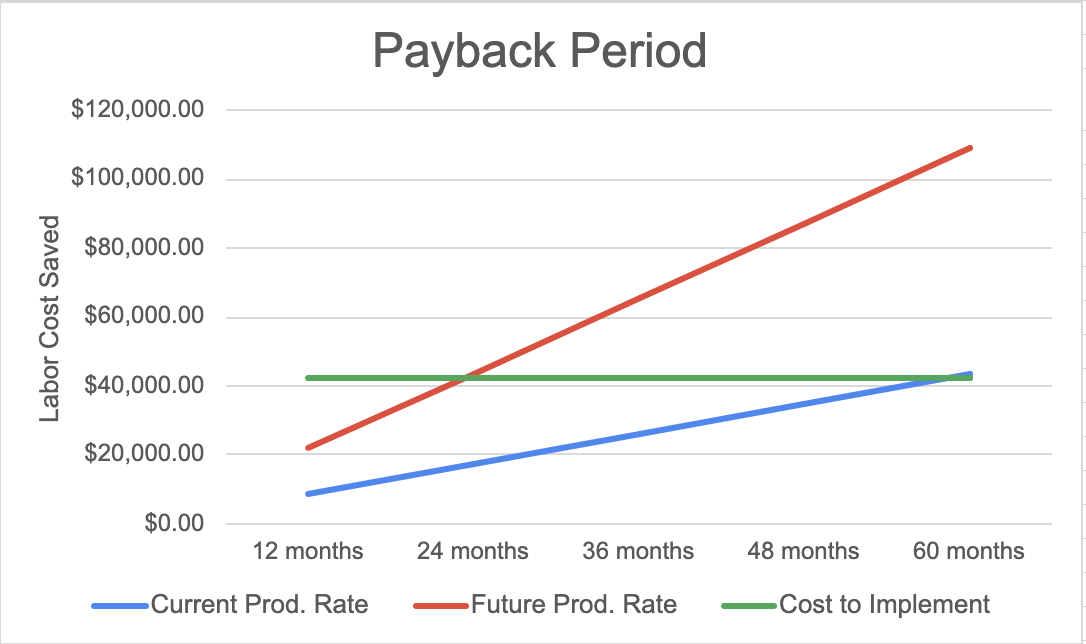

Implementation of a Collaborative Robot (Cobot) to Optimize Adhesive Bonding Process by Increasing Throughput, Decreasing Cycle Time and Waste

GKN Aerospace’s adhesive bonding process falls well short of projected growth numbers for the future. With an average production of 12 fan fairings per day, GKN looks to increase throughput by 2-4x and decrease waste. The current process is statistically out of control leading to parts sitting in quality checks for extended periods of time. Analysis of time study results revealed a massive bottleneck at the adhesive application step. The time was disproportional to the rest of the process; the highest cycle times among all the steps were related to physical application of adhesive. With all these factors in mind, implementation of a Cobot work cell would solve the major problems GKN is faced with. The Cobot is equipped with a Bipack Fancort dispensing solution that includes a 16 element static mixer to combine the adhesive parts. This process is statistically in control, reducing the need for quality control. Once fully implemented, GKN will see a project cycle time reduction of 57% as well as a throughput increase of 130%. The payback period is calculated based on reduction in labor-hours per year at the new production rate. With the increased process capability the payback period is calculated to be 25 months, whereas the current process would take 58 months. Additionally, quality control calculations for adhesive squeeze-through were performed; each run is statistically in control, a massive need for GKN. With a process that is repeatable and in control, GKN will greatly reduce material and labor spent on QC.