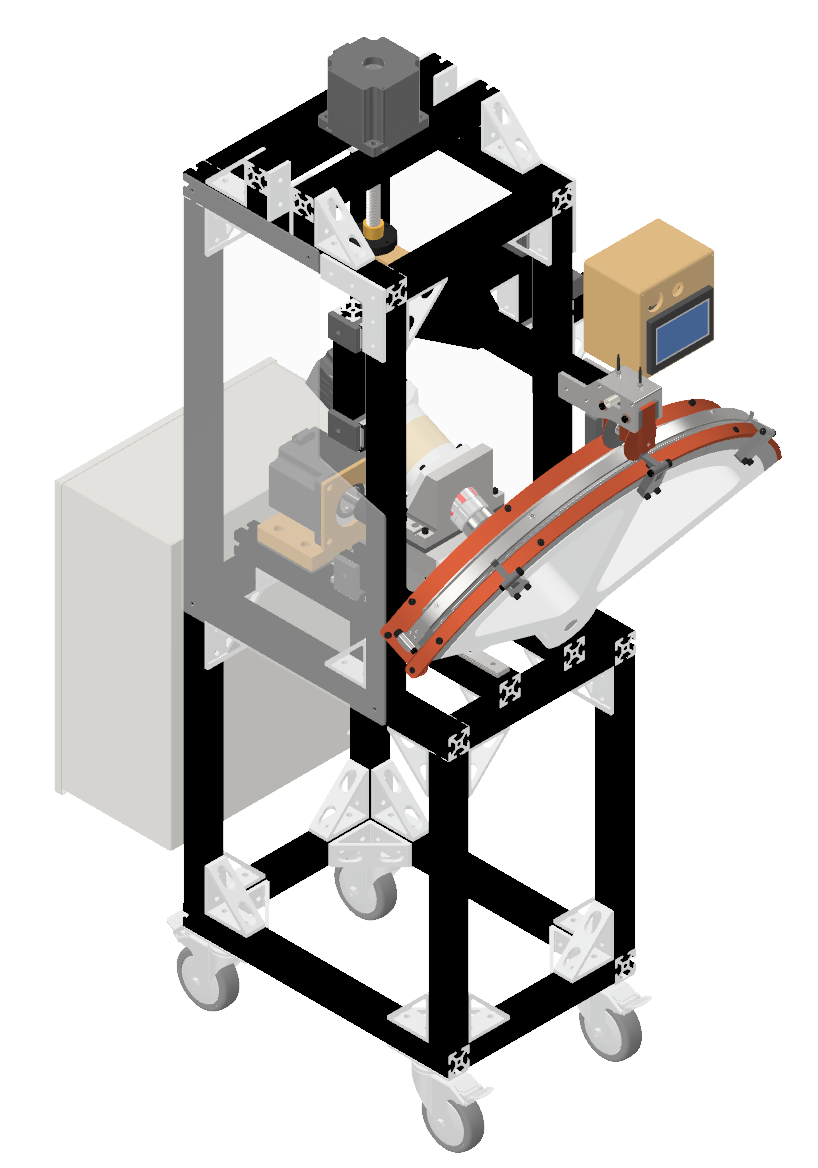

Figure 1

Team 27

Team Members |

Faculty Advisor |

Tarun Nori |

Nejat Olgac Sponsor Pursuit Aerospace |

sponsored by

Hands-Free Resistance Welder

Pursuit Aerospace is a global manufacturing company specializing in complex aircraft engine components. They have 16 locations, with this project being at the Eastford location. Pursuit's manufacturing practices have been built using Kaizen teachings, a Japanese business philosophy focused on continuously improving products and processes. The manufacturing floor consists of single-piece flow lines for part families instead of batches, allowing for better in-process inspection, minimal part travel, and dwell time. The Hands-Free Resistance Welder project was initiated by a senior design group at UConn during the 2021-2022 academic year. They made substantial progress designing and building the right-sized machine with the necessary electrical components and programming for motor operation. However, due to time constraints, they could not complete an automatic weld on the insulation blanket. All materials from the previous project have been preserved, and this group has been provided access to all CAD models, PLC programs, and design iterations by Pursuit. Using these resources, this group aims to iterate and develop this machine for production. The main reason for incorporating this machine into production is to eliminate the current welding process, which has the operators put an average of 420 tacks in one insulation blanket. This is extremely taxing on the operator, mainly their wrists, because of the repetitive motion of tacking the blankets. It also introduces human error, increasing the probability of non-conforming parts. Implementing the machine will significantly enhance production efficiency by significantly reducing manual intervention, reducing the risk of non-conforming parts, increasing production speed, and creating an ergonomic method to weld these parts.