Figure 1

Chemical and Biomolecular Engineering

Team 11

Team Members |

Faculty Advisor |

Eugene Cho |

George Bollas Sponsor Collins Aerospace |

sponsored by

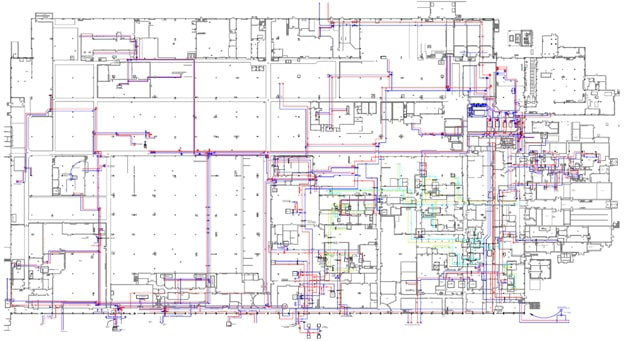

Collins Aerospace is a leading aerospace company with business interests in commercial aviation, space exploration, and defense. Various operational processes use chilled water throughout their Windsor Locks facility for cooling purposes; this is one of their most expensive utilities. Due to system age and augmentations, performance has become about 60% less efficient compared to that of the industry standard. The project goal was to recommend design changes to increase system efficiency, equipment lifespan, and ultimately reduce cost of operation. A hydraulic map of the chilled water system was first modeled within AutoCAD. This map was then used to create a hydraulic model within PipeFLO Professional. This model includes the operating characteristics of each component that influences flow within the system; this was a valuable asset when determining operational inefficiencies present within the current chilled water system. Within PipeFLO, varied parameters such as air handler speed, pump speed, type of coolant, etc. were adjusted to simulate varying operating conditions. Several cost saving improvements were recommended to Collins Aerospace from these simulation results.