Figure 1

Figure 2

Computer Science and Engineering

Team 29

Team Members |

Faculty Advisor |

Shawn Alexander |

Suining He Sponsor TRUMPF Inc. |

sponsored by

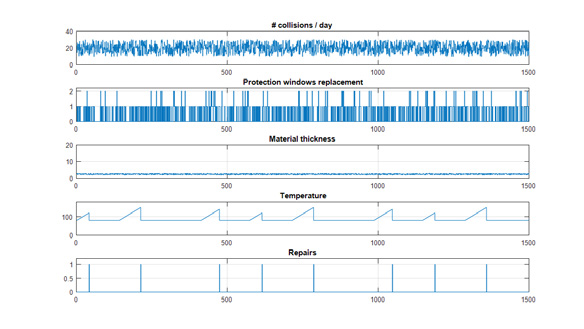

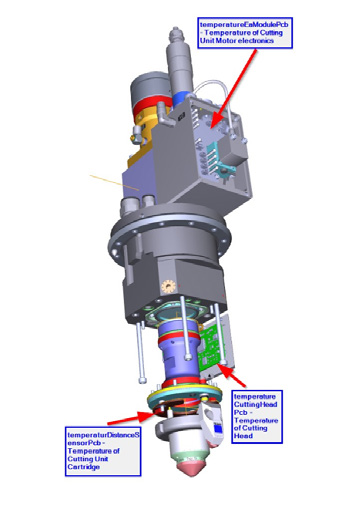

TRUMPF Inc. manufactures industrial laser-cutting machines designed to cut sheet metal. These machines are an essential part of their customers’ manufacturing processes and even a few hours of unscheduled down-time can be very costly. To minimize the chances of this, we were tasked with researching and implementing machine learning models that would be able to predict when a machine would fail or need maintenance based on its usage and sensor data. Currently, the data collected from the laser-cutting machines is limited, so to simulate the future state of TRUMPF’s data collection system, we generated synthetic datasets representing the data from 1,000 customers, consisting of a time-series log of various sensors on the machine. We used these datasets as training data for machine learning models by injecting patterns and correlations into it, and using repairs as a failure indicator. In addition to models such as a Bayesian model, we utilized clustering algorithms to identify the trends, patterns, and anomalies in the data. Our research and demonstrations will allow TRUMPF to develop their data analysis process to incorporate machine learning by replacing the synthetic datasets with real sensor data. This will assist both TRUMPF and their customers to save money by minimizing the downtime of their laser-cutting machines.