This video contains proprietary information and cannot be shared publicly at this time.

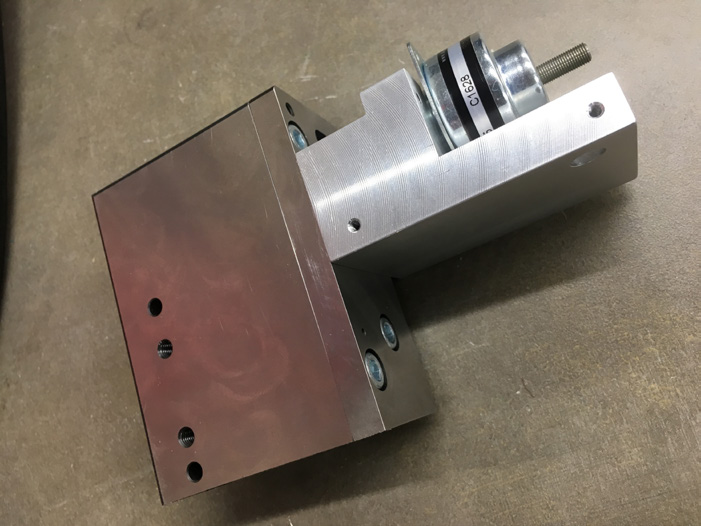

Figure 1

Management and Engineering for Manufacturing

Team 9

Team Members |

Faculty Advisor |

Daniel Castillo |

Craig Calvert, Frank J. Cunha Sponsor Sonics & Materials INC. |

sponsored by

Sonics & Materials Inc. has been a leader in the fields of both liquid processing and ultrasonic metal welding, sealing and cutting for the last 50 years. We were tasked with applying cost reduction efforts and improving serviceability to the MWS 20 ultrasonic metal welder. This device welds metal wires from .5 mm2and 40 mm2using ultrasonic vibrations to mechanically combine, unlike traditional welding. Upon close observation of all mechanisms within the device, we determined that the mechanisms moving the gather block were relatively costly for their function compared to other mechanisms in the device. Additionally, Sonics & Materials Inc. highlighted customer complaints about wire debris from previous welds decreasing the device’s welding turnover rate and serviceability. Working jointly with the ME team, we simplified the mechanism moving the gather tool by replacing it with a fixture and a linear actuator which reduced unit costs by nearly 30% while maintaining performance. We also focused our efforts on solving the issue of wire debris hurting serviceability by increasing the anvil mechanism driving force. This driving force was increased by redesigning the air cylinder and the respective components used with it. Wear improvement literature research was conducted with new coating recommendation. To conclude, a financial comparison between the old and new design was done.