Figure 1

Materials Science and Engineering

Team 11

Team Members |

Faculty Advisor |

Arseniy Bazikov |

Yuanyuan Zhu Sponsor Ulbrich |

sponsored by

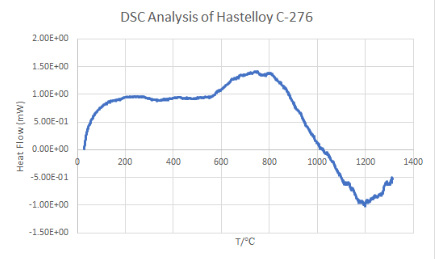

C276 is a nickel-molybdenum-chromium superalloy that is commonly used in the superconductor industry as a substrate material, upon which the superconducting layer is deposited. Ulbrich supplies C276 strips which have been rolled to various thicknesses between 30 to 120 microns. The HTSC tape manufacturers sometimes encounter problems with deposition due to surface carbides which become exposed only after the C276 substrate undergoes electropolishing; these are believed to form as a result of Ulbrich’s annealing temperature and duration. The goal is to develop a heat treatment schedule within Ulbrich’s capabilities, such that the size of the carbide particles, as well as the overall density of the particles are minimized. So far, background research suggests that the diffusion rate of various impurities has a positive correlation with temperature. Testing done with DSC on C276 suggests that there is an exothermic reaction between roughly 900 C° and 1200 C°, which corresponds with precipitate formation. DSC results will facilitate the design of an optimized annealing schedule via annealing trials and quantification of the particles that may result.