Figure 1

Figure 2

Mechanical Engineering

Team 6

Team Members |

Faculty Advisor |

Olivia Ivaldi |

Alexei Poludnenko Sponsor Mike Suba |

sponsored by

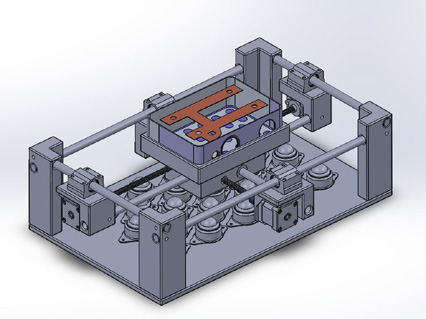

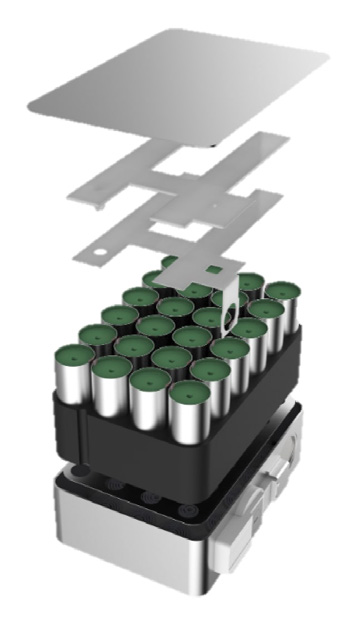

Cadenza Innovation is a Connecticut based company that designs lithium ion batteries. Cadenza’s unique “supercell” battery design provides safe and high energy density batteries at a low cost. Cadenza manufactures supercells at their facility in Bethel, CT, where they are currently automating processes on their shop floor. Part of Cadenza’s supercell manufacturing process is ultrasonic welding. Four tabs inside the supercell are ultrasonically welded to the outside housing of the battery to establish an electrical connection. This project replaces the previous manual alignment process for a supercell during ultrasonic welding. The solution is an automatic two-axis positioning system, similar to those used in 3D printers and CNC machines. The positioning system can automatically move the supercell at a speed of 100 mm/s to the positions where it needs to be welded. The system improves positioning precision to within 0.2 mm in the X and Y direction. The fixture can also withstand a vertical force of 750 N used to perform an ultrasonic weld. Ultimately, the implementation of this project reduces human interaction in ultrasonic welding, increasing the precision and speed of the welding process. These benefits ease the integration of ultrasonic welding into a large scale industrial application.