Figure 1

Figure 2

Mechanical Engineering

Team 12

Team Members |

Faculty Advisor |

Bradley C. Carrano |

Vito Moreno Sponsor Colonial Bronze |

sponsored by

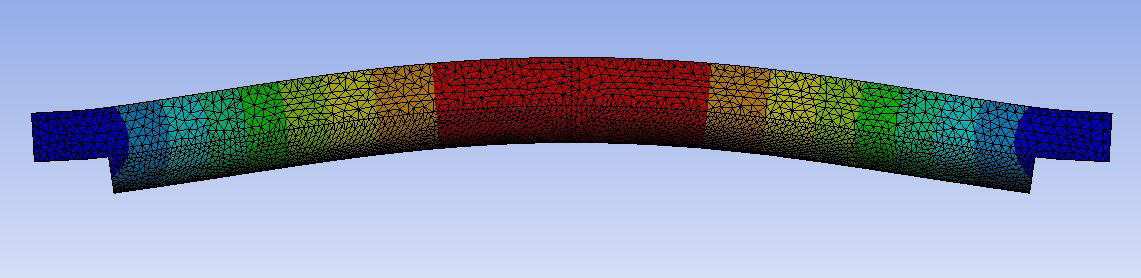

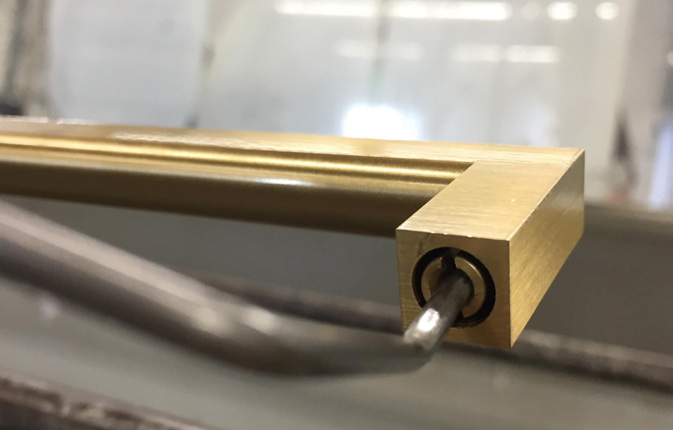

Colonial Bronze, based in Torrington, CT, makes customizable and affordable hardware out of individual components rather than one-piece forgings. This is a challenge for them because it allows finishing liquids to penetrate between the joined components causing stains which lead to part rejection. They desire to design a strong and reliable method of assembling components to make a handle that is durable, cosmetically appealing and prevents infiltration of liquids. A model of cabinet handle 745, underwent a simulation to determine the required maximum load capacity of the new design. It was found that a small meniscus of the clear coat liquid was accumulating at the end of the blind hole of the leg. It was determined that the connection method needed to be redesigned in order to either stop the entry of clear coat, or to allow it to drain out with ease. Different tests were carried out on the clear-coating of parts with changes in design & manufacturing processes. A larger size blind hole on the shank and the bottom surface being sanded allowed the surface finish liquid to drain out easily. These changes reduced the number of rejects from a cosmetic point of view.