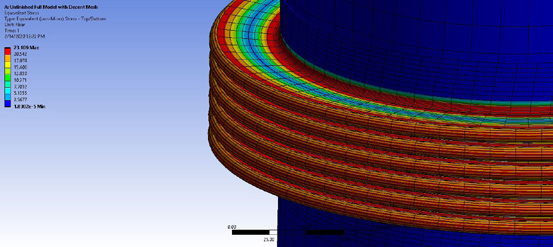

Figure 1

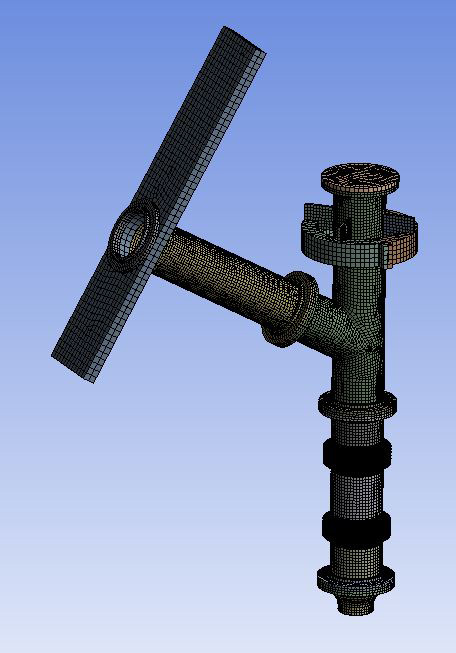

Figure 2

Mechanical Engineering

Team 17

Team Members |

Faculty Advisor |

Karen Guzman |

Vito Moreno Sponsor GE Power |

sponsored by

GE Power Creates energy and technologies of the future and improves the power networks that we depend on today. GE Power in Windsor Connecticut designs large boilers and fireboxes. One of the technologies that GE Power utilizes is a circulating fluidized bed boiler. In order to maintain combustion efficiency in the boiler an ash pipe and auger system removes dry fuel ash which is a byproduct of the combustion process. Improving the overall durability of the ash pipe will greatly benefit the customer of the systems that utilize this ash pipe. The scope of this project is to identify alternative ash pipe configurations to reduce the amount of induced stresses on the ash pipe in order to increase its overall durability. This was accomplished by analyzing the current ash pipe configuration and running FEA simulations to identify stress concentrations and other flaws within the current design. The base simulation results, in conjunction with research and testing of alternative materials, coatings and pipe configurations, was utilized to identify design concepts to lower stress and increase overall durability. Following down selection, the final design will be simulated and directly compared with the current design. The final design should achieve lower stresses and higher durability while meeting the following requirements.