This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

Mechanical Engineering

Team 35

Team Members |

Faculty Advisor |

Eamon Costello |

Julian E. Norato Sponsor Otis Elevator Co. |

sponsored by

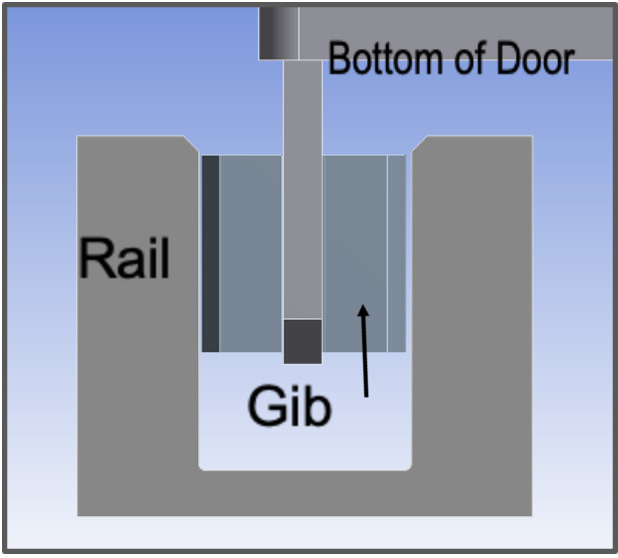

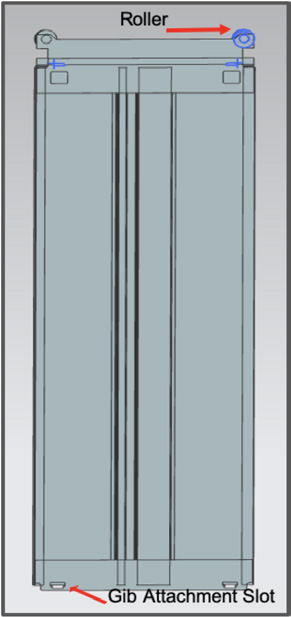

Otis Elevator Company is the leading manufacturer of safe and efficient elevators throughout over 200 countries and territories. In certain regions with high temperature differentials between the inside and outside of a building, a large pressure differential is created across the envelope of the elevator doors. This condition (known as the stack effect) is a result of colder, more dense air entering on the bottom floor while warmer, less dense air rises through the elevator shaft and exits at the top floors. This applied pressure creates friction when small plastic stoppers known as “gibs” are pinned against the channel running along the bottom of the door. This added frictional force can prevent the elevator door from closing. In an industry where consumer confidence in the product’s safety is absolutely essential, any problem undermining the normal operation of the elevator must be solved. By changing the material of the “gibs” to a very low friction material, the worst-case frictional force would no longer cause stalling. In order to minimize cost, a MATLAB code was created to identify the cheapest material that would prevent stalling on a floor-by-floor basis. These material requirements are automatically calculated based on the specifications of the building being analyzed.