Figure 1

Figure 2

Mechanical Engineering

Team 38

Team Members |

Faculty Advisor |

Tyler Howser |

Ryan Cooper Sponsor Pratt & Whitney |

sponsored by

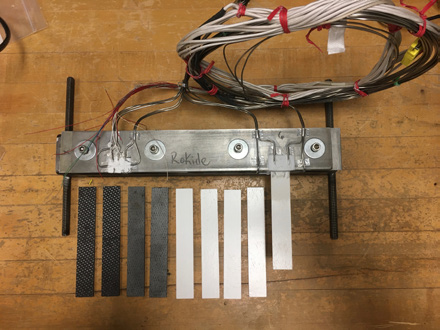

Pratt & Whitney is constantly seeking to advance the technology for gas turbine engines. Ceramic matrix composites (CMCs) are a class of materials being developed for the aerospace industry because of their light weight and ability to withstand the extreme temperatures present in gas turbine engines. In order to study the performance of these materials, specialized adhesives are required to bond various sensors to the CMC components. A commercially available adhesive has been found that performs satisfactorily for this application. The goal of this project was to gain knowledge about the strength of the adhesive’s bond and its failure mechanisms. This project started with the analysis of a cantilever beam test rig using Finite Element Analysis software (ANSYS). An experiment was designed to evaluate the strain experienced by the bond at the point of its failure. A fixture utilizing a power screw was designed and fabricated by the team to apply a known displacement to the CMC beams for comparison to classic beam-bending equations. Qualitative results were obtained with a microscopic camera capturing delamination. Quantitative results were gathered from strain gauges bonded to the CMC beams and relaying strain readings to LabVIEW. A consistent strain limit was determined for each CMC and this failure point and mechanism was provided to Pratt & Whitney.