Figure 1

Figure 2

Mechanical Engineering

Team 45

Team Members |

Faculty Advisor |

Ian Hancock |

Ryan Cooper Sponsor Pratt and Whitney |

sponsored by

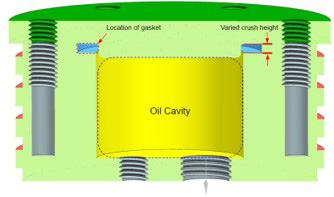

Our goal is to simulate flight effects on the gasket by performing vibration, thermal, and pressure testing. The vibration test will vibrate the seal at a frequency of 100 Hz at an acceleration of 10 g’s for 150 hours. The thermal test will heat the seal from 100 °F to 500 °F for 3000 cycles. Lastly, the pressure test will load the seal from 0 to 500 psi for 1000 cycles. During each test, the gasket will be torqued down inside a test rig designed by the team; utilizing six test rigs that torque down the seal at different crush heights ranging from .015 - .040 inches. The success criteria will be found during the pressure test after the seal undergoes thermal and vibration testing. When a seal fails during pressure testing, oil leakage is seen with a UV flashlight through the use of fluorescent dye mixed into the oil. If a graphite seal goes through each test without leaking, there is evidence to support its ability to adequately replace the currently used spiral wound graphite with metal backed gaskets.