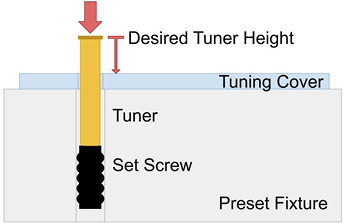

Figure 1

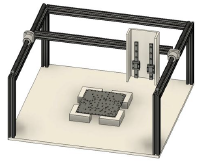

Figure 2

Mechanical Engineering

Team 49

Team Members |

Faculty Advisor |

Chase Harmon |

Bryan Weber Sponsor Radio Frequency Systems |

sponsored by

Radio Frequency Systems (RFS) is a leading, world-wide provider of radio frequency solutions including microwave and base station antennas and various communications cables and connectors. The goal of this project was to design and build a machine that automatically places height restrictors on preset fixtures. The preset fixture is a template used to produce tuning covers for a radio frequency (RF) filter, a key component in communications devices. RF boards use deep-drawn brass tuners for signal processing; the height of the tuners is what creates the desired signal output. By setting the preset fixture depth through a mechanical system, versus the current manual methods, RFS can reduce fine-tuning time of RF boards by roughly 50%. Set screws were chosen to be the height restrictors for the preset fixture. The required vertical tolerance of ±0.005” was achieved via a photoelectric time of flight sensor laser mounted above the drive system. Confirmation of the machine’s tolerance and repeatability were conducted by precise measurements of a test preset fixture. Shaker table testing was conducted on the selected screw to ensure expected preset use would not shift the screws beyond allowable tolerances.