Figure 1

Figure 2

Team 8

Team Members |

Faculty Advisor |

Jon-Marc McGregor |

Anson Ma Sponsor Unilever |

sponsored by

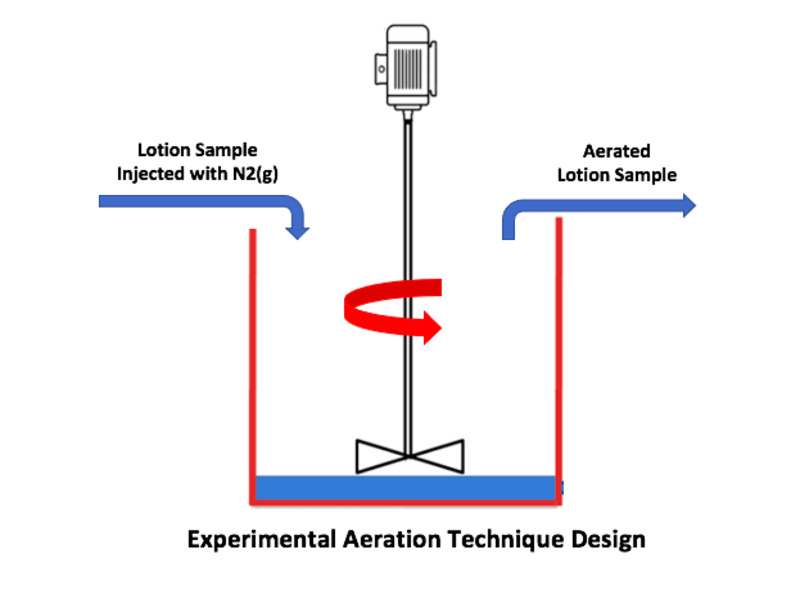

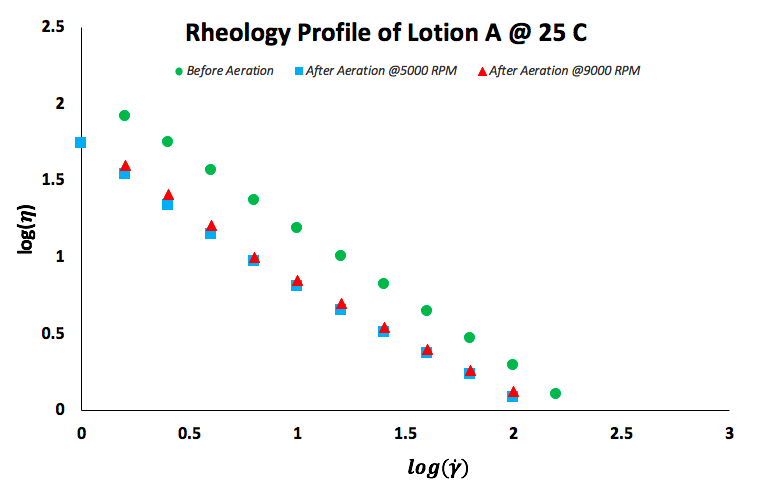

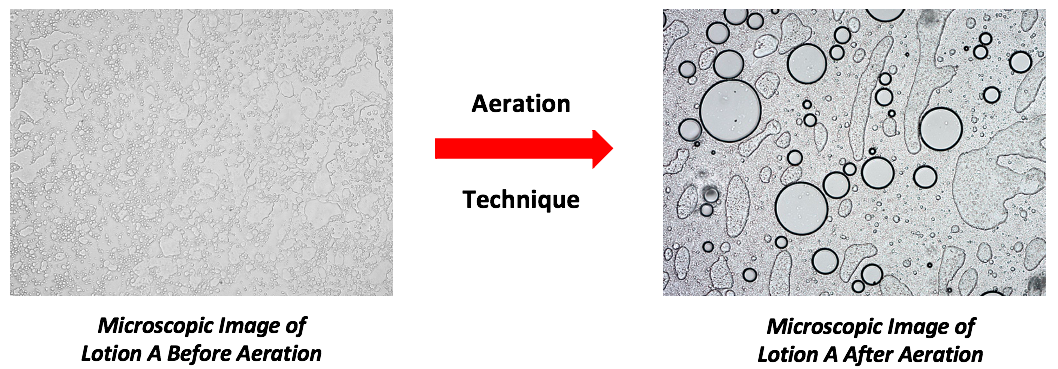

On any day, approximately 2 billion people use Unilever skin variant products such as lotions, cream, gel, etc., to look good, feel good and get more out of life. However, the company faces the challenge of continuously creating products with a unique whipped appearance and feel heavily desired by their customers. Unilever has attempted many different aeration techniques to improve product sensory but has not yet developed a single process that works on several skin variant products. Our project then aimed to expand on current research efforts and develop an aeration process that will lower the specific gravity and guarantee a stable product before it reaches the consumer's hands. Our team designed a robust and scalable aeration method, which incorporates a high shear mixer in conjunction with a nitrogen gas injector, to tighten bubble size distribution and maximize the number of bubbles present in the product. The leading theory behind our design is that bubble breakage occurs once the capillary number of lotion samples exceeds the critical stress for each skin variant with known fluid properties. The team carried out a series of experiments to serve as bench-scale proof of concept for our design. To evaluate our finished product's life span, the team conducted a few stability test methods that looked at the foam's pH, smell, and volume change. Implementing our technical solution will advance Unilever's outlook in the skincare market and thus retain and attract new customers.