Figure 1

Figure 2

Team 49

Team Members |

Faculty Advisor |

Ryan Torres |

Dr. Jason Lee Sponsor Pratt & Whitney |

sponsored by

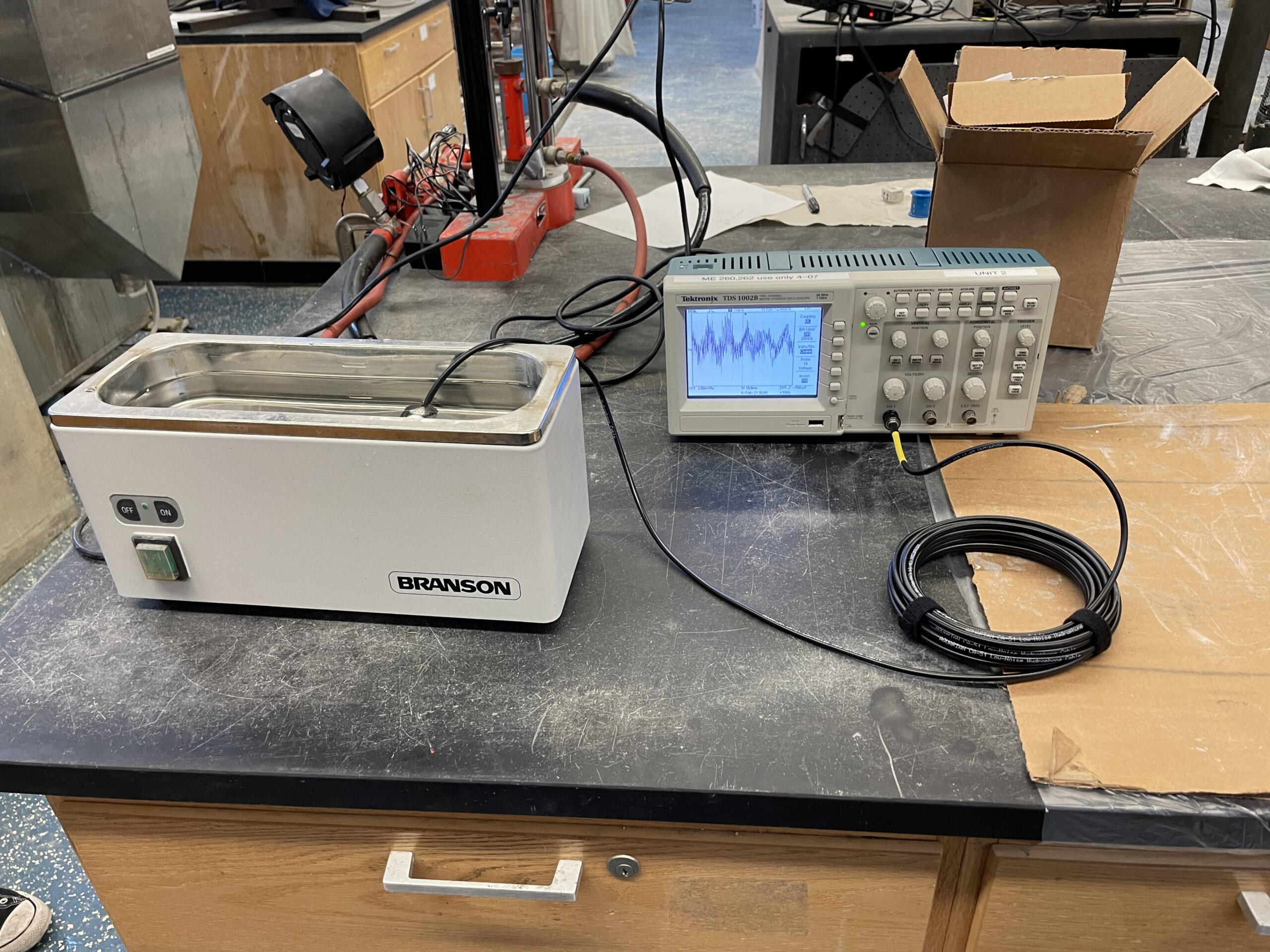

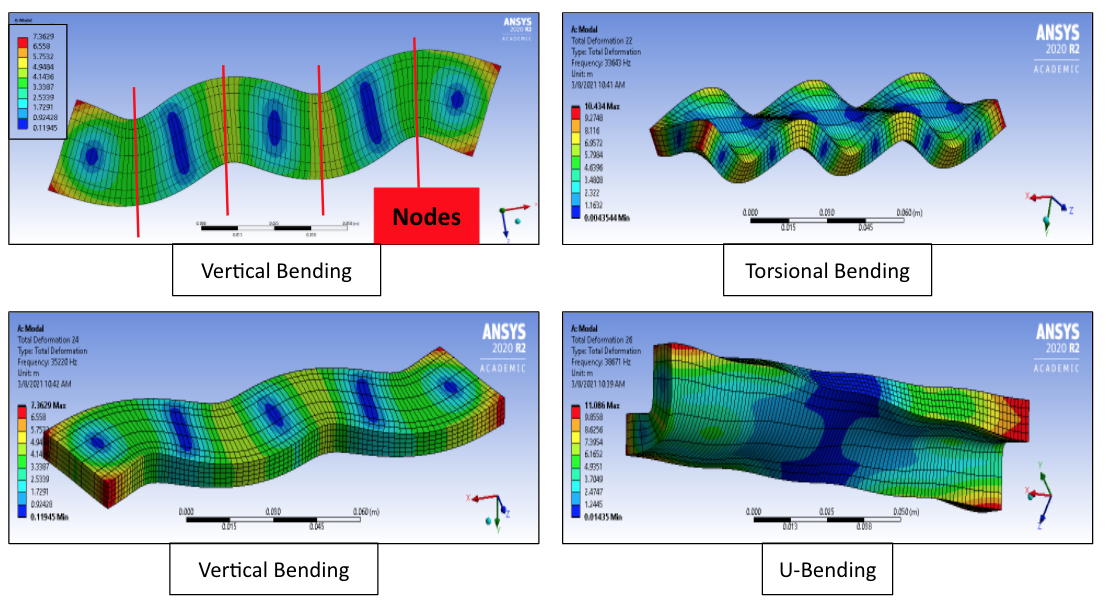

The objective of this project is to determine whether or not ultrasonic cleaning has a significant effect on the fatigue life of gas turbine components. Ultrasonic cleaning is commonly used to clean parts after they have undergone other industrial processes in order to rinse away residue and loosened particulate matter. Ultrasonic cleaning uses ultrasonic waves to excite water or another solution in a bath. This causes cavitation bubbles to form on the surface of a part within the bath, and when those bubbles collapse, a small jet of water hits the surface of the part, removing dirt or grime from it. The concern is, if the object in the bath has a similar natural frequency to the operating frequency of the cleaner, the part could be excited and damaged. In our approach we designed multiple parts of different geometries that had the same natural frequency of the ultrasonic cleaner, which oscillated between 34,000-37,000 Hz, with an average frequency of 35,200 Hz. We then exposed the parts to the cleaner for over 10 hours to simulate repeated cleaning sessions of turbine parts over their lifetimes. Since parts are normally cleaned for 5 minutes at a time in the industry, running them in the bath for over 10 hours simulated about 120 individual cleanings. We then analyzed the parts using a dye penetrant kit to help detect any stress/fatigue cracks. The dye penetrant test did not indicate any damage. We believe this is because the first mode of natural frequency of an object is where it experiences the highest loads. Since the natural frequency of the bath excited the 6th mode of the parts, it did not cause a high stress or strain. In addition, since the frequency of the bath oscillates, it is not always the same as the natural frequency of beams while it is running, so the part is not always being excited. From our tests, we have determined that ultrasonic cleaning will not affect the fatigue life of turbine components that are cleaned without being in contact with other parts and are cleaned in a bath that has an oscillating frequency.