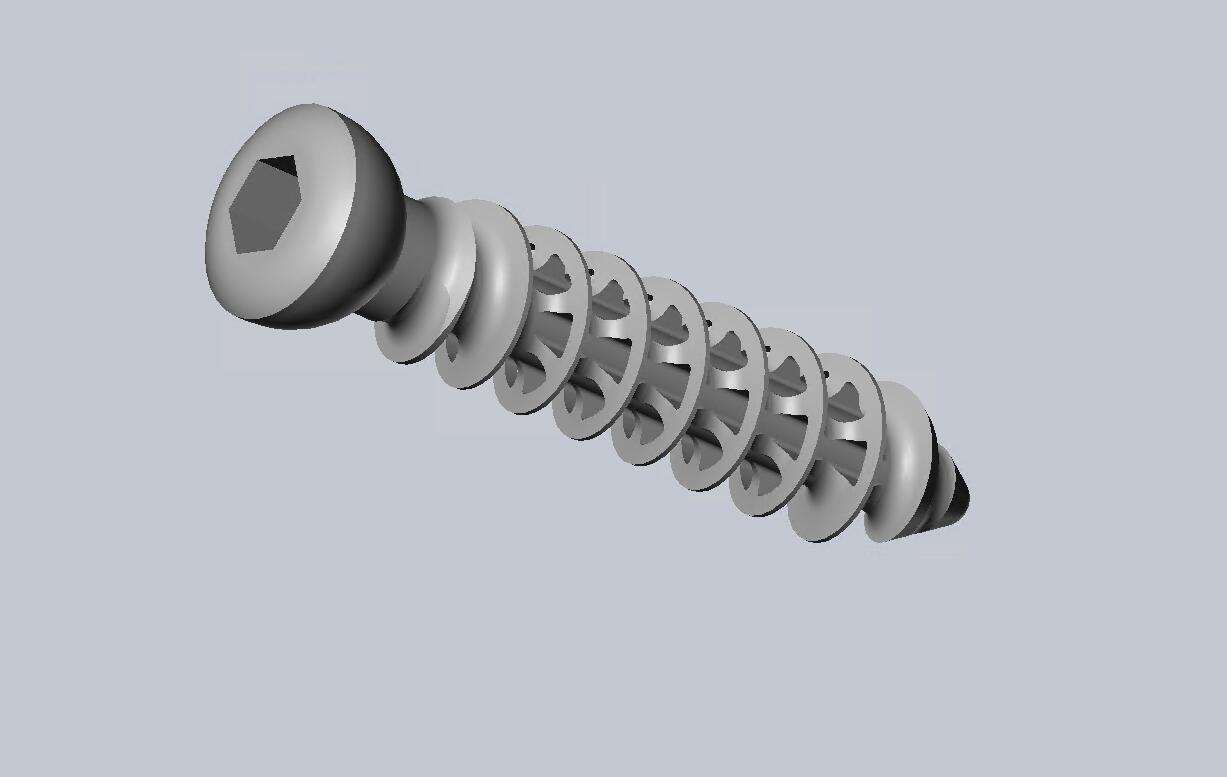

Figure 1

Team 70

Team Members |

Faculty Advisor |

Matthew Bonvicini |

Julian Norato Sponsor Kolb |

sponsored by

In 2008, our sponsor, Eric Kolb, created a consulting company known as Kolb Consultants with a focus on improving several aspects of everyday life. These aspects were fitness, health care, and manufacturing. More specifically, one of the things he looks to improve and optimize are orthopedic bone screws. The scope of this project was to research the ASTM Standard for bone screws and to test Mr. Kolb’s bone screw design with apertures in a SolidWorks model. This allowed us to see if the screw did or, with some design changes, could meet the requirements for certification. We also modeled and tested a traditional bone screw to validate and compare results. We researched existing orthopedic bone screw designs as well as the material they are made of. Once we had a foundational understanding of that, we began to research and understand the wide range of bone densities that are present in the human body. This was important in correctly applying the tensile and shear strengths that correspond to a particular bone. To determine if the screw could withstand the different forces within the body, we conducted a finite element analysis. This was key in determining if Mr. Kolb’s aperture design was optimized. We concluded that Mr. Kolb’s screw design is capable of withstanding the needed forces and a physical screw should be created and tested.