Figure 1

Figure 2

Team 12

Team Members |

Faculty Advisor |

Anna Clinkscales |

Dr. Jennifer Pascal Sponsor University of Connecticut |

sponsored by

Sponsor Image Not Available

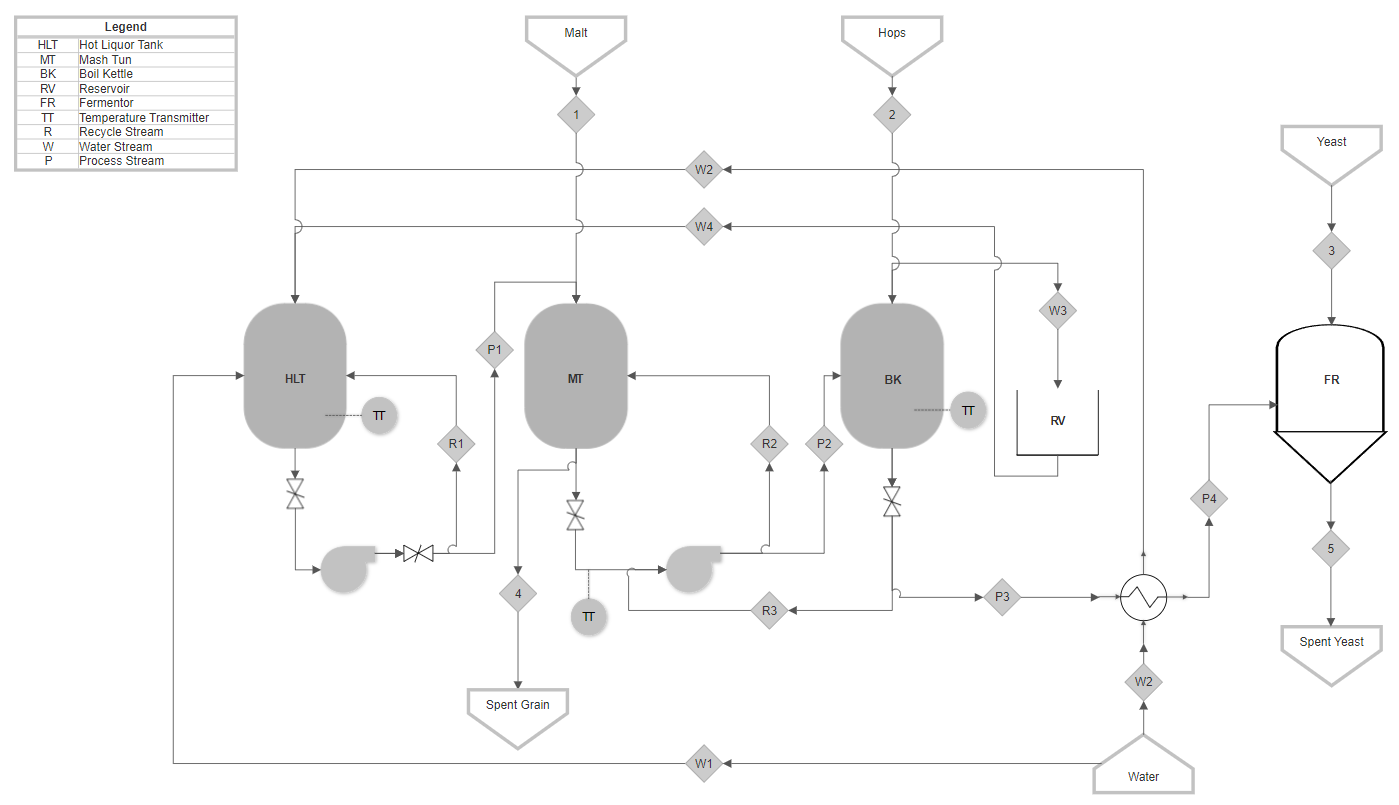

On-Campus Pilot Scale Brewery

Since 2012, the number of craft breweries in the state of Connecticut has more than tripled, with more than 30 of them being owned by UConn alumni. This has led to a boom in the number of breweries and the styles of beer available, especially in the state of Connecticut. The style, flavor, and rate of production of beer are determined by chemical engineering principles, making chemical engineers well equipped to optimize beer production. The goal of this project is to design an on-campus, pilot-scale brewery. With industry and academic knowledge, we designed a 1 barrel (bbl) pilot system that is user-friendly for students with limited brewing experience. We performed a comprehensive capital and production cost analysis based on a production rate of 1000 gallons per year. Our group determined the size of equipment needed to maintain this production, as well as the demand for raw materials, water, and energy. Since brewing is a water-intensive process and generates wastewater, we thoroughly reviewed ethical and environmental considerations. With these factors in mind, we were able to design an amber ale recipe that was both easy to brew and palatable to a wide range of people, using the concepts of mash efficiency, hop bittering, and fermentation kinetics. We incorporated this recipe into a standard operating procedure (SOP) for the pilot system design to guide future engineering students who wish to get involved in brewing science at UConn in the future.