Figure 1

Figure 2

Team 15

Team Members |

Faculty Advisor |

Rayne Santiago |

Matthew Stuber, PhD Sponsor Other |

sponsored by

Modeling and Redesign of Temperature Control Systems for Reactors

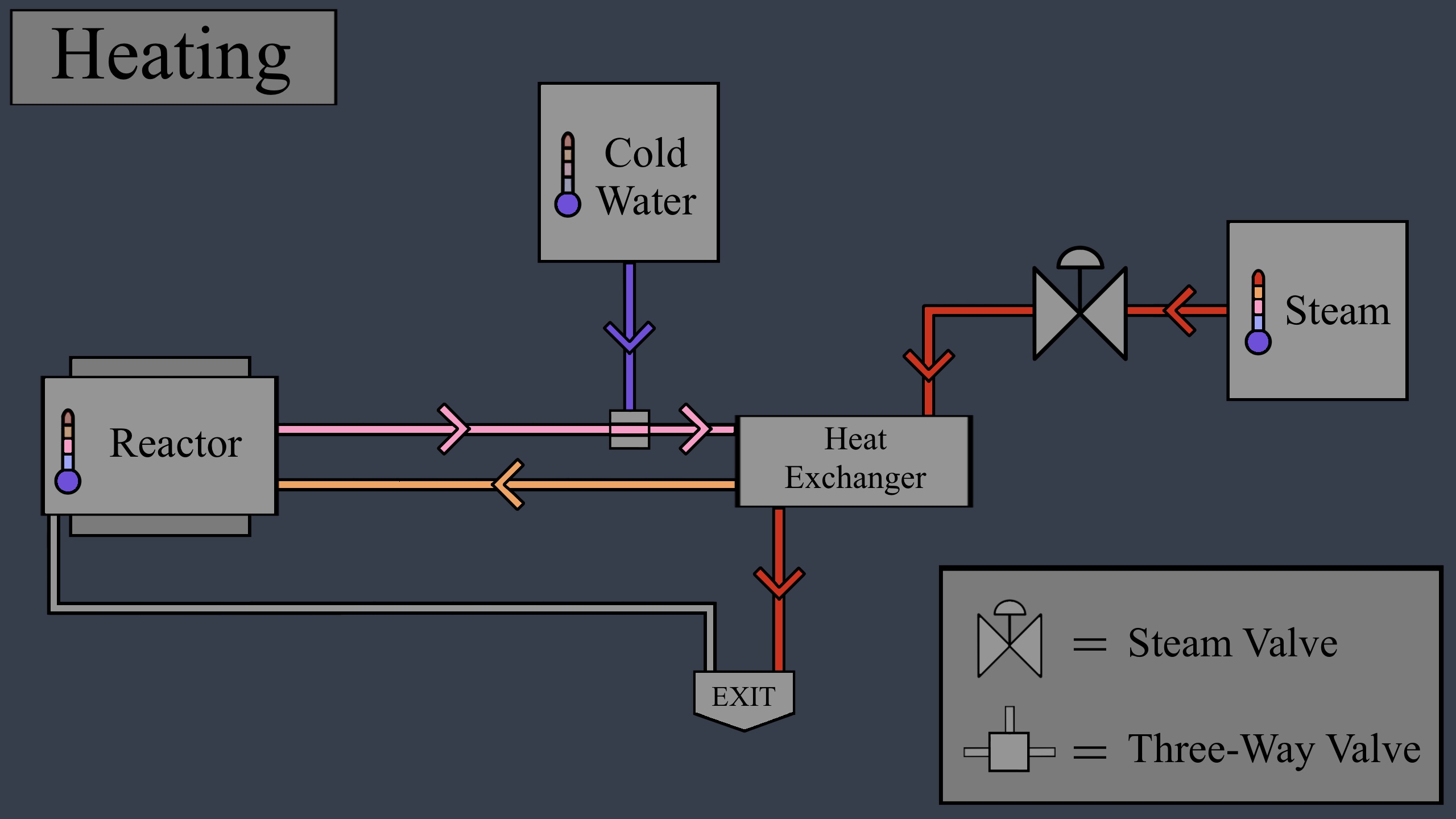

Bomar Specialties is a global corporation that manufactures oligomers used in various UV Cure applications, such as nail polish and 3D printing. Oligomers are medium molecular weight chemical compounds formed by reacting several smaller molecules together. The reaction temperature is critical to the reaction consistency of the oligomers. Bomar’s process uses jacketed reactors. The jacket controls the reaction temperature to facilitate molecular interactions and prevent hazardous reactor conditions. The jacket temperature is adjusted through a piping loop containing a heat exchanger. For heating, steam from a boiler is fed into the heat exchanger while the loop fluid recirculates in a Closed Loop Configuration. For cooling, chilled water is introduced to the loop while in an Open Loop Configuration. Currently, operators manually adjust the temperature setpoint of the jacket loop to modulate the reactor temperature. This manual control method has several drawbacks, notably the variation between operators in modulating the reactor temperature, and the potential for incorrect temperature setpoints to be input. The goals of this project are to show the benefits of automated temperature control and to investigate the implementation of a cascade control system into Bomar’s process. We used MATLAB to model the reactor temperature to the heat transfer through the reactor walls. The model plots economic savings in temperature control for both processes. In addition, we looked at Bomar's existing controllers and recommended the proper equipment that can use a cascade control system. This control system would allow Bomar to maintain a more consistent and economical oligomer production.

Our team collaborated with Management & Engineering for Manufacturing 9 on this project.