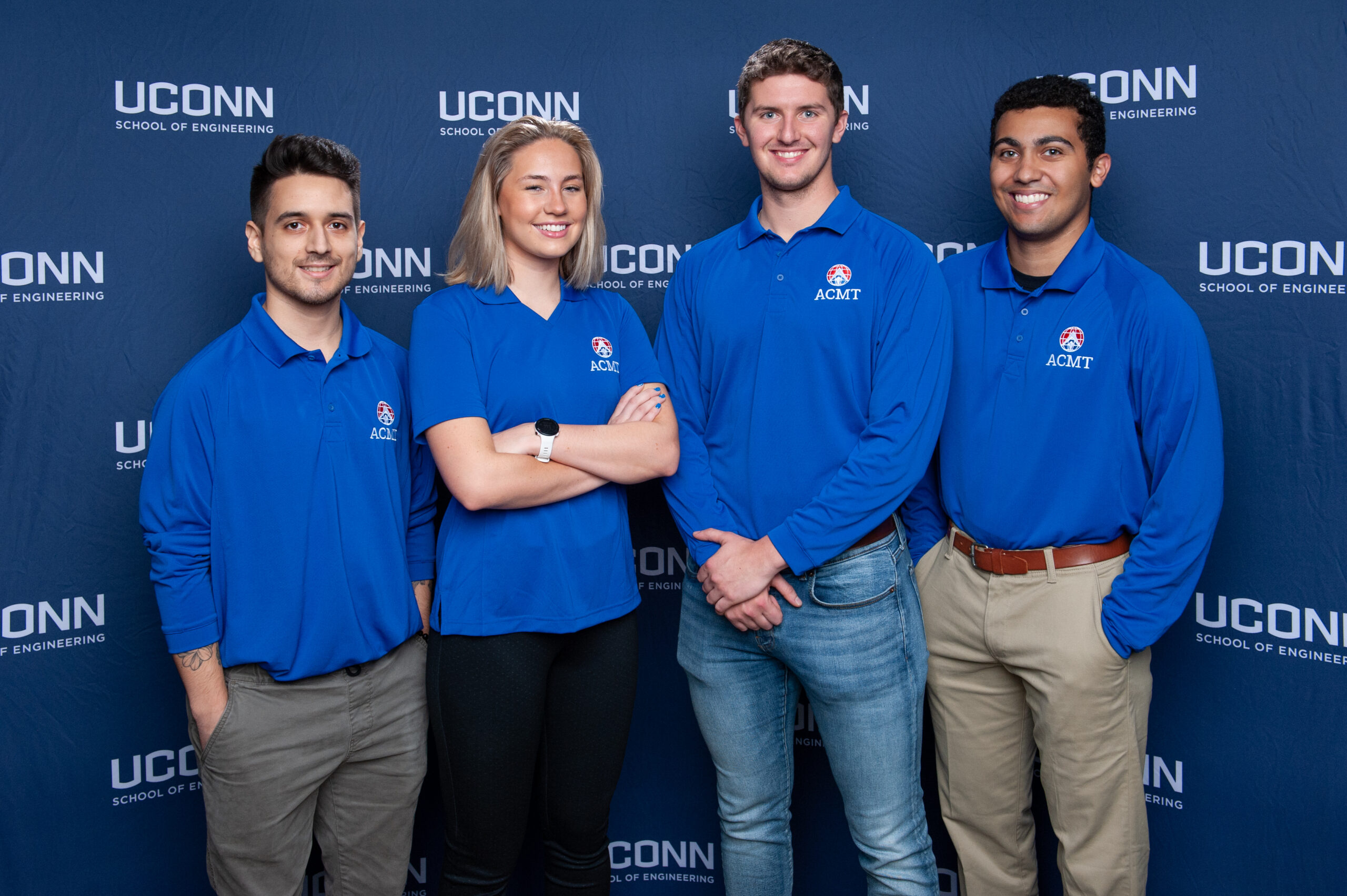

Figure 1

Team 1

Team Members |

Faculty Advisor |

Jack Herms |

Vito Moreno Sponsor ABB |

sponsored by

Feasibility of Robotic Welding of Complex Aluminum Panels

This project demonstrates the feasibility and capabilities of an ABB robot equipped with a TIG (tungsten inert gas) welding head to weld complex aluminum panels. Aviation is a volatile industry and companies are constantly looking for ways to improve speed and efficiency in their manufacturing processes. The use of robotic arms are becoming more common in industry as a way of speeding up repetitive tasks while still maintaining high quality products. Companies are also exploring the use of robotic arms for the safety benefits of higher risk tasks such as welding. TIG welding provides a multitude of challenges for the robot arm. It requires precise movements and timing for the heating and cooling of the metals. Variables such as current, voltage, speed, and feed rate will be adjusted to create a quality weld. Specific fixturing and tooling will be required to complete specific tasks. This project explores the robots ability to perform quality welds that are acceptable in the field of aviation where requirements and tolerance are extremely crucial.

Our team collaborated with Electrical and Computer Engineering 20 on this project.