Figure 1

Figure 2

Team 13

Team Members |

Faculty Advisor |

Matthew Donlon |

Thomas Mealy Sponsor Chapman Manufacturing |

sponsored by

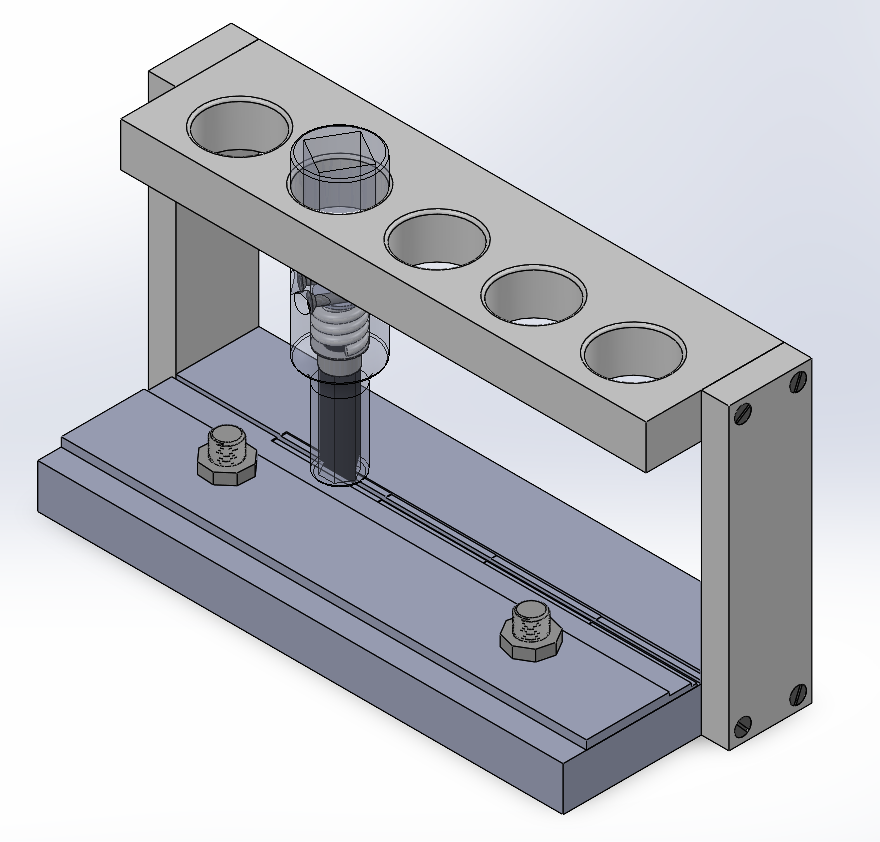

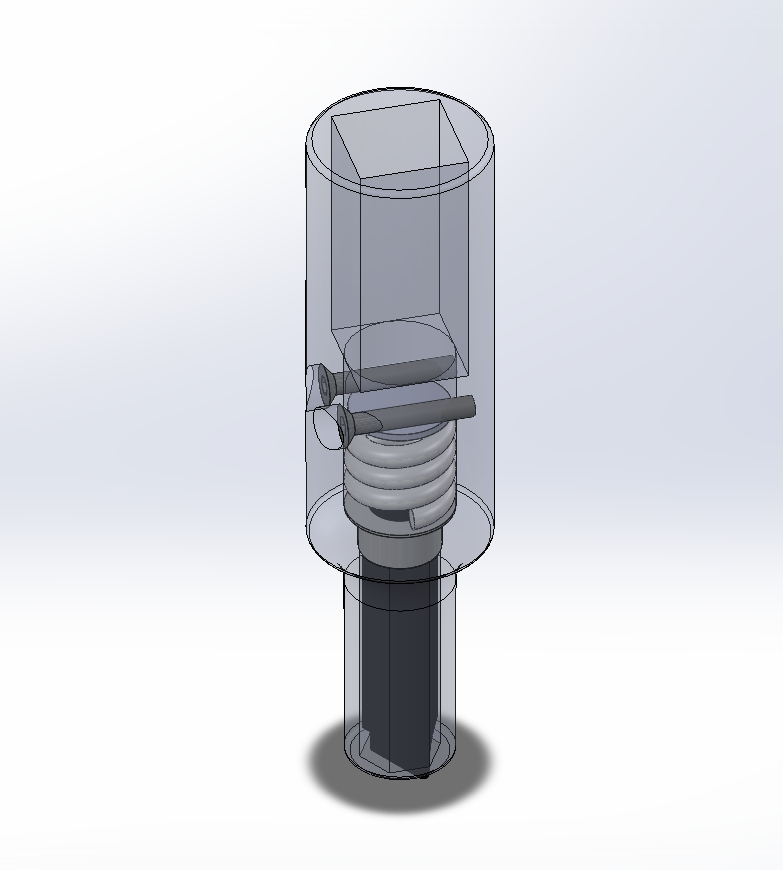

Torque Capability Test Fixture Design

Chapman Manufacturing has tasked Mechanical Engineering Team 13 with redesigning their torque capability test fixture. The purpose of this project is to design and optimize a new testing fixture for Chapman Manufacturing with improved accuracy, ease of use, and efficiency when testing and switching between different slotted screwdriver bits. Our objective is to develop a practical and ergonomic fixture that will provide accurate and reliable results with less human observation required. The testing process should be replicable and routine in its set up, with consistent readings between different operators and testers. The most important criteria our team focused on throughout the design process were reliability, safety, and ease-of-use/ergonomics. During preliminary torque tests with the previous Chapman fixture, there were readily apparent issues the team had to focus on. These issues included both the concentric and orthogonal positioning of the bit with regards to where torque was being applied as well as how each bit was secured, respectively. These issues were addressed by using a sliding plate with fasteners to secure each bit orthogonally to a respective slot height setting in tandem with a concentric plate positionally mounted above each height setting, ensuring that the bit holder has minimal angle deviation when torque is applied. Five height settings were chosen to sufficiently account for the varying contact areas of individual bits. Another issue found during testing was the cam out forces present when applying torque. A loaded spring mechanism was incorporated into the bit holder component to counteract these forces.