Figure 1

Chemical and Biomolecular Engineering

Team 23

Team Members |

Faculty Advisor |

Zach Adler |

Yongku Cho Sponsor Chemical and Biomolecular Engineering |

sponsored by

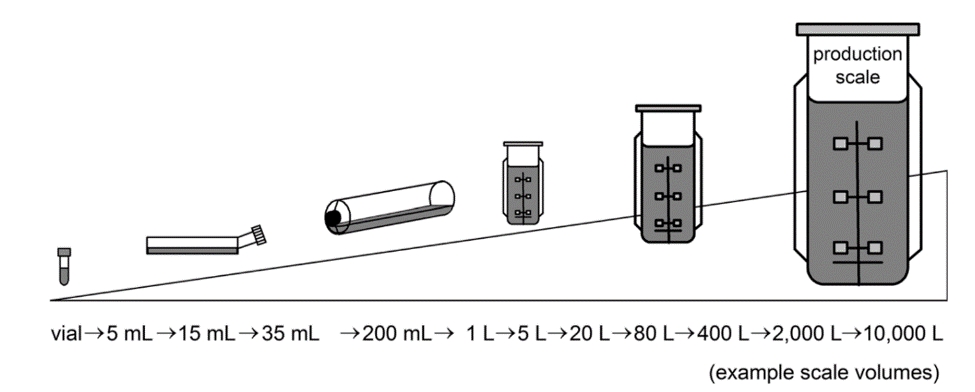

Antibodies can effectively treat numerous diseases. The scientific community must therefore develop a cost-effective and efficient process to increase antibody production and meet market demand. To fulfill this objective, we will use a seed train process in which cells grow in successive reactors until the production bioreactor scale is reached. Our team’s goal was to minimize the time cells spend in the seed train, as this accounts for nearly half of the antibody production process. By reducing the overall processing time, pharmaceutical companies can produce more antibodies at a lower cost. Using an innovative membrane bioreactor design, we sought to change several key parameters such as the number of bioreactors required and the volume of bioreactors within the seed train. We implemented a computational model that solves coupled cell growth equations while also finding optimal passaging times between reactors. We then compared our model’s time-to-market profit and total cost to literature sources. Along the way, we considered the potential safety hazards of developing a large-scale process as well as potential sources of contamination. Our model demonstrates that it is possible for computational methods to expedite the current production process of antibodies and in turn provide essential medications to those who rely on them.