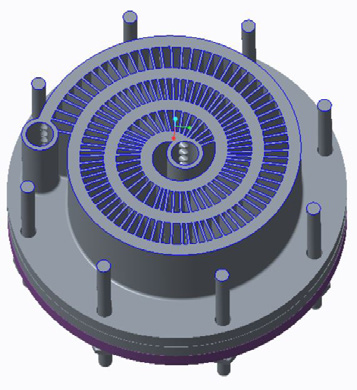

Figure 1

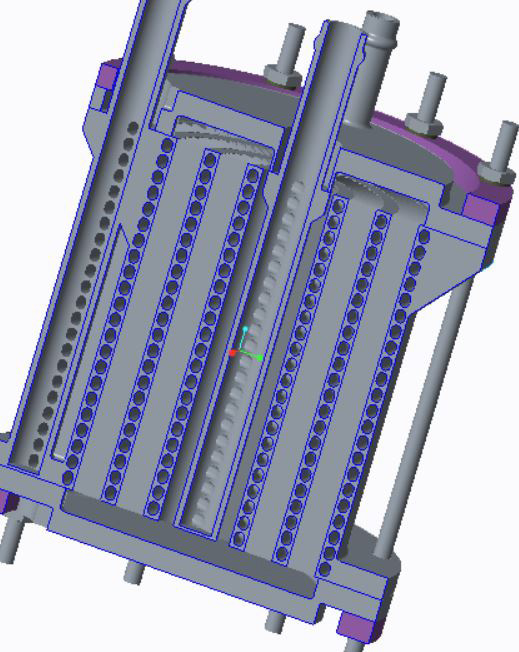

Figure 2

Mechanical Engineering

Team 11

Team Members |

Faculty Advisor |

Jonathan Petersen |

Ugur Pasaogullari Sponsor Collins Aerospace |

sponsored by

Collins Aerospace, created by the 2018 combination of United Technologies Aerospace Systems (UTAS) and Rockwell Collins, has helped shape the aerospace and defense industry for more than a century. UTAS designed the space suits worn by America’s first astronauts, and Rockwell Collins provided the communications equipment used by every American astronaut. In space, thermal management and heat rejection is critical. The goal of this project was to design, create, and test a functional and scalable single fill port Phase Change Material (PCM) heat exchanger (HX). A PCM HX is an effective way of storing thermal energy without increasing temperatures above its operating limits in the environmental control life support system (ECLSS) of a spacecraft. The newly designed PCM HX would incorporate a single homogenous PCM body created through the additive manufacturing process. The motivation for this design was the cost savings incurred by eliminating the time consuming braze step and wax fill process. To validate the solution’s accuracy, a model HX was 3D printed and then tested using varying coolant flows. These flows produced pressure drops as well as heat transfer rates which were used to determine overall thermal efficiency. Due to the model’s scalability, all data collected can be further applied to a full scale model capable of handling the thermal demands of a spacecraft.