This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

Mechanical Engineering

Team 14

Team Members |

Faculty Advisor |

Allan Bakker |

Vito Moreno Sponsor EA Patten |

sponsored by

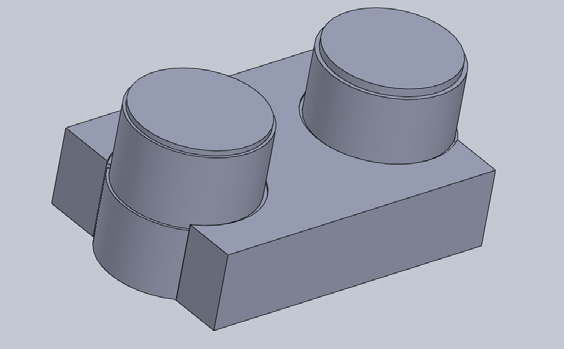

EA Patten is one of the world’s leading custom metal tube fabricators used by diverse industries. Our goal is to research, design, fabricate, and validate a prototype fixture that aims to reduce the cycle time needed to test similar features on jet engine tube fittings, while meeting the rules and regulations of the current inspection method. EA Patten inspects each part’s specific measurements using tools such as verniers and micrometers to ensure that all are within specification. Thus,EA Patten manufactures jet engine tube fittings faster than they can inspect each part.Our purpose is to design a go/no-go type fixture that will test multiple parameters for multiple features covering more than one size.The motivation to decrease the time required to complete the cycle time for testing familiar parts is needed to keep up with the increasing demands of jet engines today. Intensive research was conducted on the current inspection process to develop prototype fixtures for the features currently being manufactured today. Using CAD software, we designed multiple fixtures and narrowed down the best ideas. The fixture was 3D printed, machined, and tested on current tube fittings. By creating test fixtures that are specific to the feature instead of the part numbers, the inspection process is expected to see a significant reduction in inspection time.