This video contains proprietary information and cannot be shared publicly at this time.

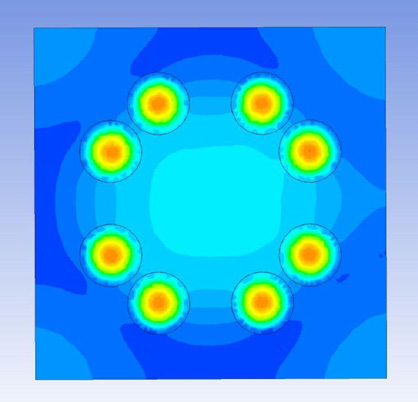

Figure 1

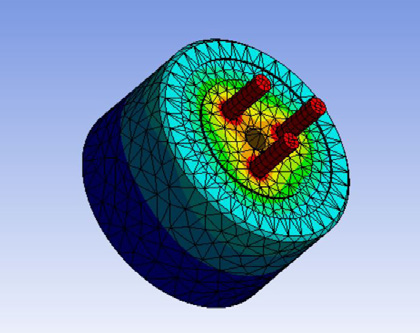

Figure 2

Mechanical Engineering

Team 19

Team Members |

Faculty Advisor |

Tyriq Green |

Bryan Weber Sponsor Gentex Optics |

sponsored by

Injection molding a popular method in the manufacturing industry due to its ability to produce large amounts of products at once. This process is used to produce a variety of everyday objects, such as plastic food containers, toys, and water bottles. Our sponsor, Gentex Optics, currently uses this technique to manufacture polycarbonate lenses for eyewear. Its parent company, EssilorLuxoticca, owns over 20 luxury brands such as Ray Bans, Michael Kors, and Oakley. The team’s goal in this project is to reduce cycle time through investigation of the areas in the process that deal with the greatest thermal energy, and to identify methods to improve heat management of the process. The team found that 90% of the heat in the system is contained in the mold block, and 70-85% of the cycle time is attributed to the cooling time. Thus, the team created a design that modifies the interior of the mold block to allow the block to cool faster.