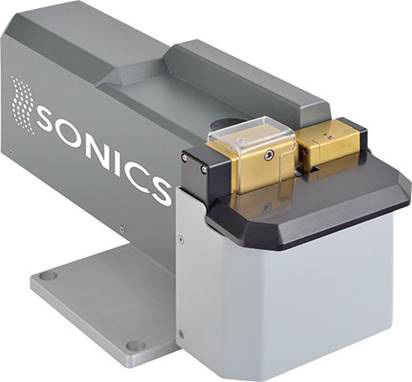

Figure 1

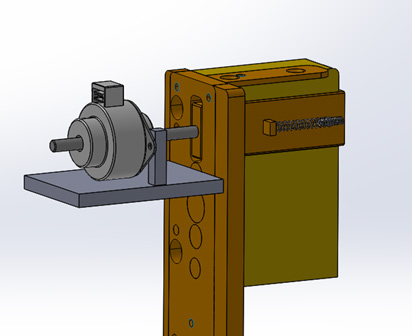

Figure 2

Mechanical Engineering

Team 51

Team Members |

Faculty Advisor |

Ermin Behremovic |

Jason Lee Sponsor Sonics and Materials |

sponsored by

Sonics & Materials, Inc., is a pioneer and leader in the field of ultrasonic welding and ultrasonic liquid processing. Sonics’ ultrasonic metal welding product line is used for bonding conductive and dissimilar metals, such as copper, aluminum, brass, gold and silver. This project focused on Sonics’ 20 kHz wire splicer. Both the gathering tool and the anvil mechanism on this machine were identified as areas for improvement. By analyzing the machine’s weld process, the wire splicer was evaluated for manufacturability and reliability. A mechanical model of the wire splicer was created to understand the function, cost and manufacturing complexity of each component. This allowed the team to meet the project objectives by developing a variety of solutions. To reduce the overall complexity of the machine, the gathering tool and anvil mechanism designs were simplified. The team improved the gathering tool by upgrading from a rotary pneumatic system to a linear spring system. This modification significantly reduced the number of components in the assembly, resulting in a 32% cost savings, and simplified the manufacturing process by reducing or eliminating complicated alignments. The anvil mechanism was improved by upgrading the air cylinder to deliver greater force. This modification prevents wire debris from jamming the assembly, improving serviceability and reliability.