Figure 1

Figure 2

Mechanical Engineering

Team 53

Team Members |

Faculty Advisor |

Alexander Ney |

Reza Sheikhi Sponsor Stanadyne |

sponsored by

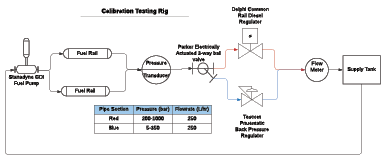

Stanadyne is a major manufacturer of gasoline and diesel injection pumps with a testing facility located in Windsor, CT. Stanadyne is looking to increase their testing capabilities for their gasoline direct injection (GDI) pumps by replacing their current pressure regulators. The maximum pressure Stanadyne can test at is 350 bar. To understand the conditions in which their product fails, they requested an electrically actuated regulator capable of modulating pressures ranging from 5 to 1000 bar. After doing extensive research of market offerings, it was concluded that multiple regulators would be needed to effectively cover the desired pressure range. A solenoid regulator used in common rail diesel engines was sourced due to their ability to handle high pressure. This will be combined with the low pressure regulator Stanadyne currently has installed in their test stands. A 3-way pneumatic powered diverter valve was added upstream of the two regulators to divert the flow based on the incoming pressure. This system will be installed in their durability and calibration test stands. A control protocol was then developed to allow the new system to integrate directly with their current testing software.