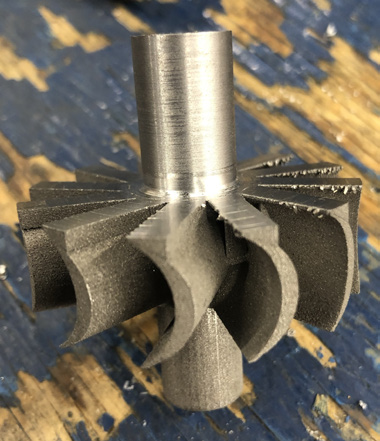

Figure 1

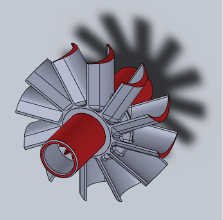

Figure 2

Mechanical Engineering

Team 58

Team Members |

Faculty Advisor |

Steven Doan |

Tianfeng Lu Sponsor Bill Dalton |

sponsored by

Developing an effective and reliable fuel pump for the aerospace industry is an issue brought to the University of Connecticut’s Mechanical Engineering Department by Triumph Engine Controls. One of the biggest issues for aerospace fuel systems is multi-phase and multi-component fuel. A two-phase/two-component mixture and bubbles are formed due to the following factors: pipe friction, changes in elevation, various forces and g-forces. For consistent and reliable operation, the fuel needs to be in a liquid phase. The LOLA is a fuel pump that takes this two-phase/two-component mixture and dissolves or condenses the bubbles to a liquid. At the outlet of the pump, this ratio is zero seeing how all the bubbles are condensed to a liquid. Once the V/L ratio reaches this limit, the pump will choke and lose its functionality due to such a low acoustic velocity. Triumph Engine Controls has provided the team with a baseline wheel and the team has further developed two design iterations based off of previous test data. Due to the complexity of this pump, computational fluid dynamics does not accurately predict the performance and choking point of the pump. Since casting is a very long, timely process, the team has been tasked with utilizing and investigating additive manufacturing as an option to create these wheels and test for research purposes.