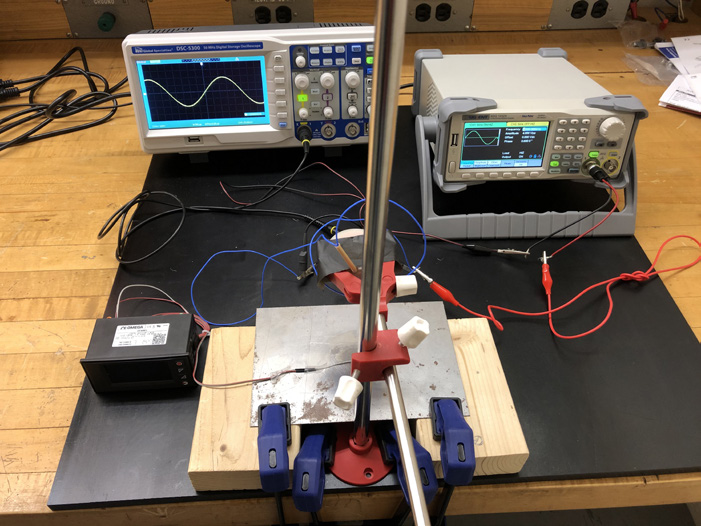

Figure 1

Management and Engineering for Manufacturing

Team 12

Team Members |

Faculty Advisor |

Alex Biron |

Frank J. Cunha, Craig Calvert Sponsor Sperry Rail Services & Transportation Infrastructure Durability Center (TIDC) |

sponsored by

Sponsored by the US Department of Transportation, the Transportation Infrastructure Durability Center, and Sperry Rail Services, we designed and built a testbed to demonstrate how non-contact forces can be used to detect faults in metals, with the specific application of railways. This testing method works by observing the dynamic responses produced by inducing a Lorentz force in the metal. This method aims to decrease time and labor input for testing railroad tracks for cracks. The testbed uses an electro-magnetic transducer, which consists of a coil of wire wrapped around a neodymium magnet. The magnetic field produced from the transducer generates eddy currents in the piece of metal being tested. We use an oscilloscope to measure how the current in the coil changes when a defect is present in the metal. The testbed is used to showcase how the non-contact testing works and it will reside in UConn’s MEM lab for future MEM courses to use as a data collection system. This method has applications in a broad range of railroad testing scenarios and has potential for application in businesses that monitor and inspect infrastructure. The future work for this project entails scaling up our proof of concept into a system that can move down a railway track and alert operators when the oscilloscope indicates a defect.