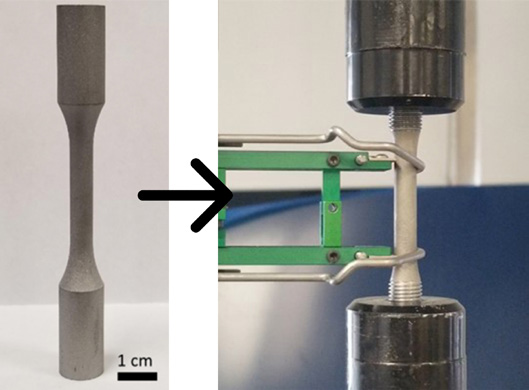

Figure 1

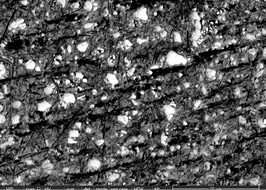

Figure 2

Materials Science and Engineering

Team 4

Team Members |

Faculty Advisor |

Megan Bright |

Seok-Woo Lee Sponsor Sikorsky - A Lockheed Martin Company |

sponsored by

Additive manufacturing, especially of metallic alloys, is an ever-growing field in industry. It provides a faster, more efficient method of prototyping and producing parts. Direct metal laser sintering (DMLS) utilizes a high-power laser to melt a metal feedstock powder to create complex part geometries in a fraction of the time compared to traditional casting and forging techniques. In aerospace, Al6061 is the most commonly used aluminum alloy due to its superior mechanical properties and light weight. However, Al6061 experiences poor particle adhesion due to its thermal properties and low silicon content, making it a challenge to manufacture parts with desirable mechanical properties using DMLS. In contrast, AlSi10Mg experiences excellent particle bonding during the DMLS process, resulting in superior mechanical properties in comparison to DMLS Al6061, but worse mechanical properties than wrought Al6061. Through the use of heat treatment processes, this project and Sikorsky Aircraft aim to achieve similar mechanical properties to Al6061, but with DMLS AlSi10Mg. Successful heat treatment, mechanical testing, and microstructural analysis will help further advance the understanding of the effects these heat treatment procedures have on AlSi10Mg and additionally allow Sikorsky Aircraft to implement and optimize processes that will pave the way for use of the alloy on aircraft.