Figure 1

Figure 2

Materials Science and Engineering

Team 7

Team Members |

Faculty Advisor |

Kevin Sala |

Lesley D. Frame Sponsor Pratt and Whitney |

sponsored by

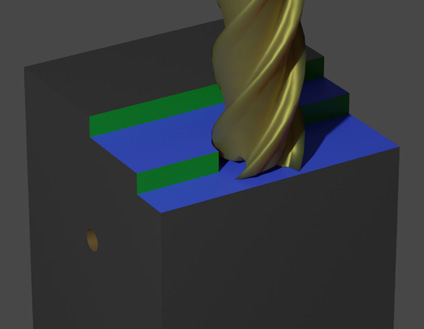

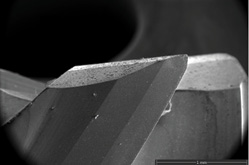

In the aerospace industry, high precision parts are needed to maximize safety. Designing a manufacturing process to reduce the number of scrapped parts while maintaining safety standards is critical. A key issue when machining is the formation residual stresses. Relaxation of these created residual stresses can lead to distortion of a part. Typically, heat treatment is used to remove or reduce residual stresses within the material. However, the required precision for each part does not allow aerospace components to be heat treated after machining. Understanding how residual stresses are introduced during machining is a crucial component in optimizing the entire manufacturing process and could allow residual stresses to be controlled during machining. In this project residual stresses were introduced into a titanium alloy, Ti6242, by machining. The vertical and horizontal cut depths were varied to examine the impact different tool paths had on residual stresses. X-ray diffraction was used to determine the magnitude of residual stress at the cut surfaces. Various other characterization methods including electropolishing, optical light microscopy, and scanning electron microscopy were also used to examine the surface and subsurface damage.