This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Team 7

Team Members |

Faculty Advisor |

Patrick Adamczyk |

George Bollas, Jeremy Huffman, Geoffrey Moeser, Miki Oljaca Sponsor Cabot |

sponsored by

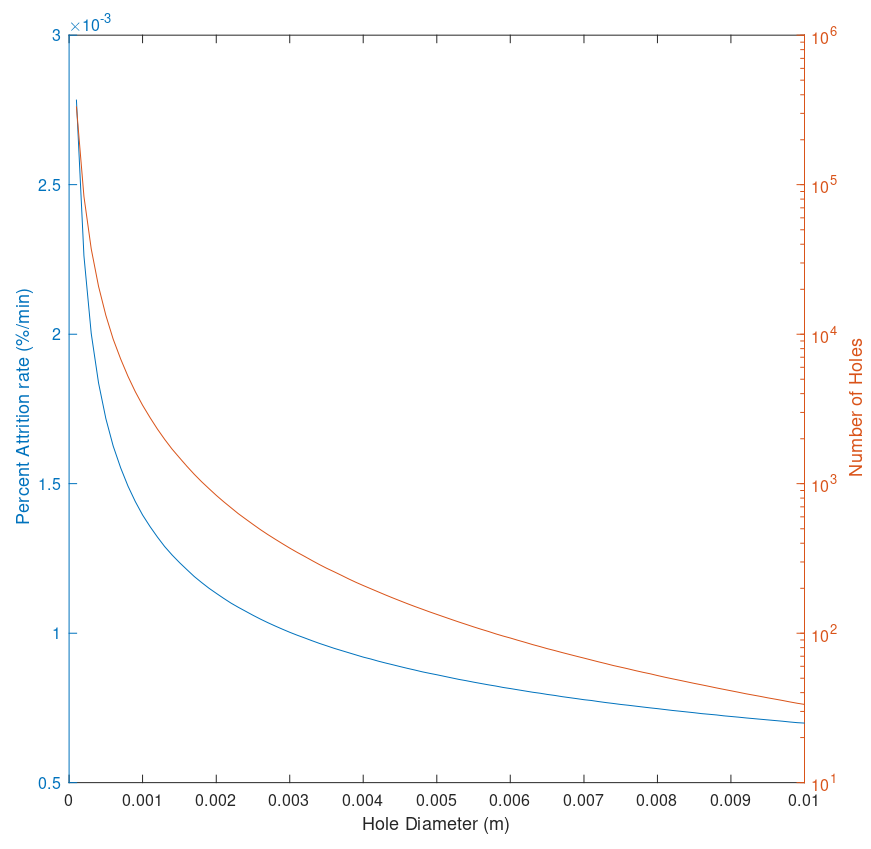

Fluidized beds are a novel process within the chemical engineering world, used in areas such as fluidized bed reactors, solids separation, and fluid catalytic cracking. Improvements in fluidized beds can have a substantial impact as more fluidized beds are implemented in various processes, replacing less efficient processes such as liquid-solid mixers with associated dryers. The goal of this project is to optimize the design for a grid plate within a fluidized bed in order to minimize attrition, the unintentional breakdown of particles. A fluidization software for modeling, in conjunction with Matlab will be used to theoretically calculate attrition rate. This will be done with multiple types of popular grid designs, such as perforated plates, pierced-sheet grid, and cap type. Results will then be compared with experiment. Carbon black has low to no carcinogenic effects, however mechanical irritation of the eyes, skin, and lungs can occur. Additionally long term inhalation of carbon black dust, produced after attrition of carbon black, causes lung disease. The impact of an optimized grid has the potential to decrease the dust produced with carbon black, therefore decreasing the chance of lung disease by carbon black, as well as decreasing waste as attrited material is generally disposed of.