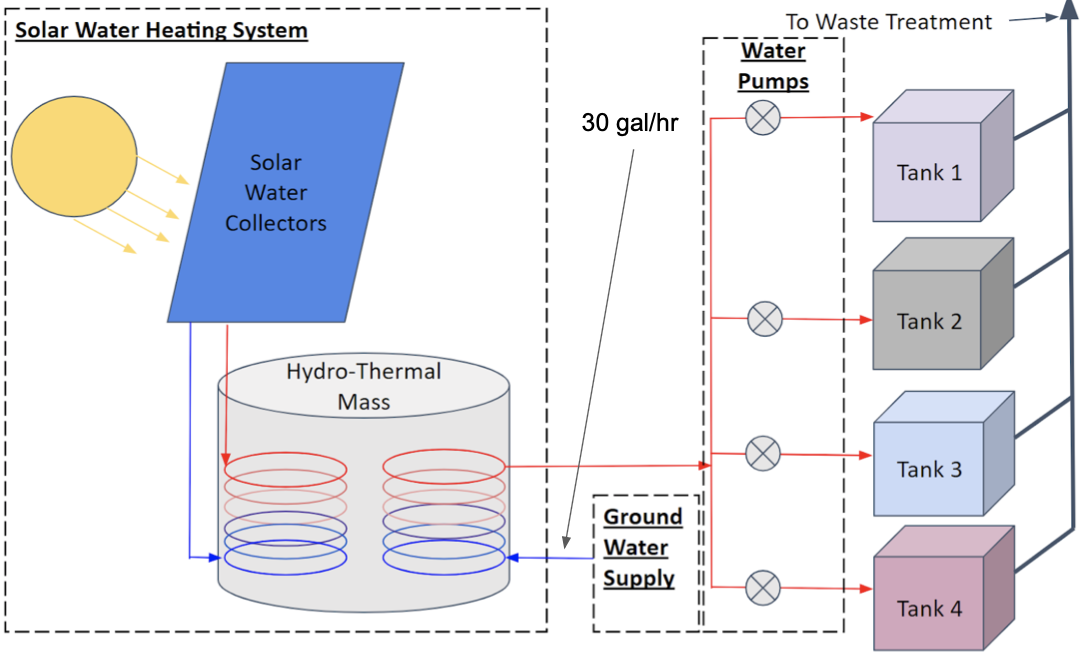

Figure 1

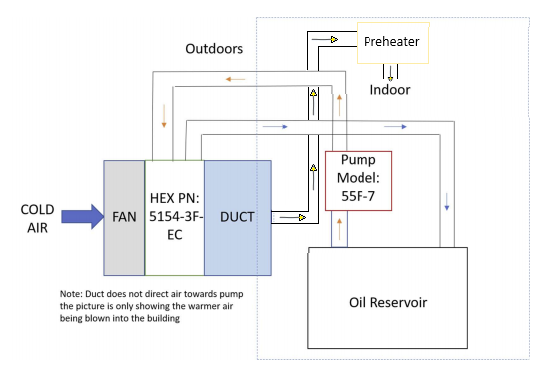

Figure 2

Team 5

Team Members |

Faculty Advisor |

Sabrina Dibble |

Frank J. Cunha, Craig Calvert Sponsor Holo Krome |

sponsored by

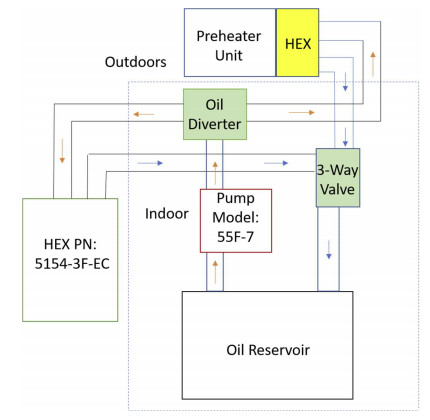

Holo-Krome, a Connecticut based company, specializes in high quality fasteners ranging from bolts to screws and studs. An important goal for company executives is to reduce spending on manufacturing processes, while also making the company more environmentally friendly. Holo - Krome’s production of high strength fasteners requires heat treatment via a continuous furnace line to get desired hardness and tensile strength. This process results in waste heat that is exhausted through a heat exchanger. The company decided that this waste heat may be an area in which they can save money while also working toward becoming a more green company. This was the basis of our project. The project focused on achieving a method of recovering the lost heat and utilizing it to preheat outside air during colder temperatures/winter months in order to provide comfort heating to the building. A key incentive was to reduce the levels of gas consumption used in preheating air for the building. Students created three designs. Upon calculating the achievable cost savings and efficiency for each design, it was determined that the three waste heat recovery designs did not provide a high enough cost savings or efficiency to justify implementation. As a result, students proposed the company achieve its cost savings and sustainability goals via the use of solar water heaters. The solar water heaters will preheat the water used in the finishing process for the fasteners. If implemented, this will allow the company to use less electricity in the finishing line, thus contributing to both of the key goals.