Team 6

Team Members |

Faculty Advisor |

Kevin Perez |

Francisco Cunha and Craig Calvert Sponsor Jacobs Vehicle Systems |

sponsored by

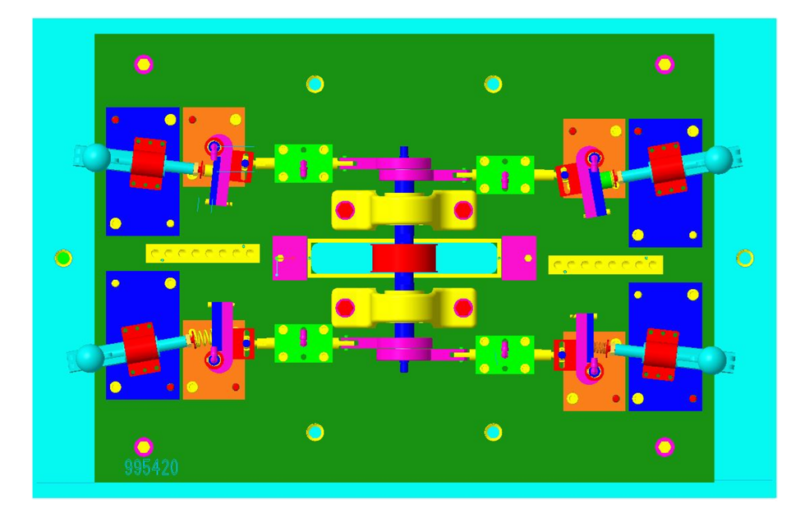

Jacobs Vehicle Systems is a global leader in engine brake technology in the trucking industry. They specialize in the manufacturing of engine brakes and valve actuation technologies. Our group was assigned the task of updating Jacobs current spring fatigue test stand so that it can take into account both the linear and bending motion of their new rocker bias springs. We accomplished this task by designing a spring test stand that emulates the environment the rocker would be in if it was in the the engine to make sure the spring is compressed as how it would be in engine application. Our design has a rocker arm, a modular spring seat, and a modular spring pre-loader baseplate that can replicate how the spring would be compressed in engine application. Our design allows for springs to be tested under different rocker and engine applications. By having a spring fatigue test stand that accurately measures the spring life, the springs are less likely to fail while they are on customers's engines. If these springs break on the engine it will cause the engine brake to stop working properly and may even cause damage to engine components leading to engine failure. Creating a spring test stand that successfully measures fatigue life of spring will greatly benefit Jacobs by reducing the warranty costs associated with premature failure of springs in engine.