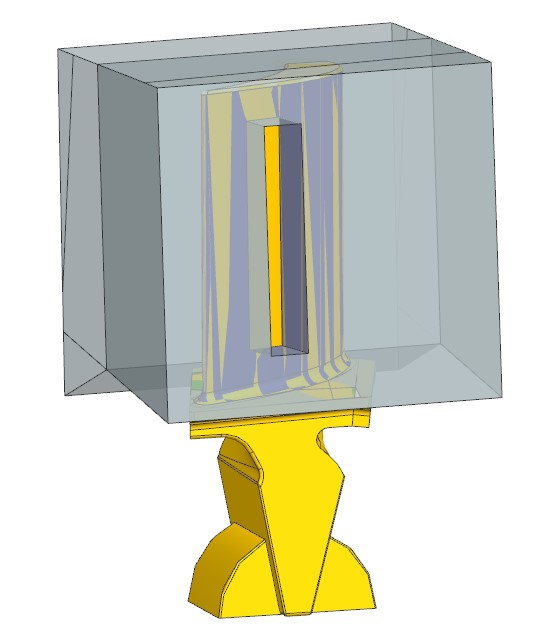

Figure 1

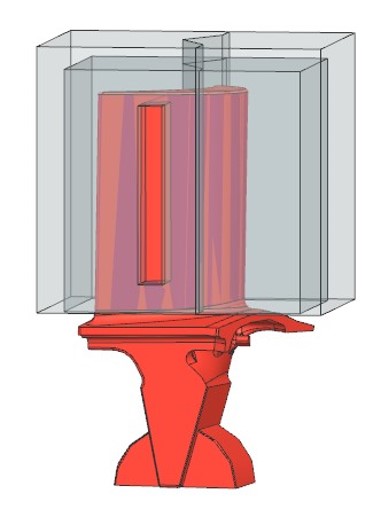

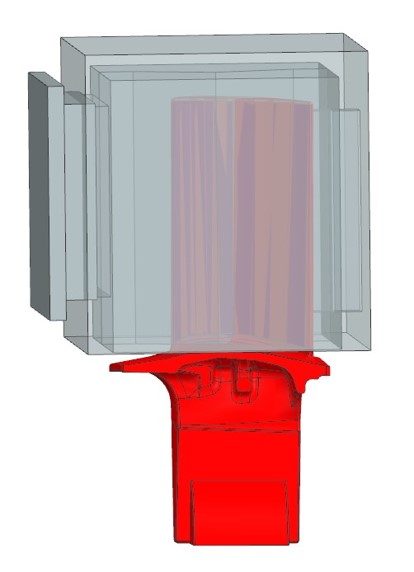

Figure 2

Team 39

Team Members |

Faculty Advisor |

Calvin Colby |

Tianfeng Lu Sponsor Pratt & Whitney |

sponsored by

The objective of this project is to improve upon the process of temporarily blocking cooling holes in turbine blades and vanes during testing. During one stage of testing, Pratt & Whitney must cover the cooling holes on their turbine blades and vanes in order to test that the airflow design distribution is met. The holes must be unblocked after testing is completed. Pratt & Whitney currently uses a wax-and-tape method that takes almost 2 hours on average to apply, test, and remove. Pratt & Whitney is looking to decrease that time by 90 minutes and create a process where the materials blocking the holes are reusable. Our team was provided with a turbine blade and told which holes should be blocked. For our design, a rubber mold was 3D-printed to fit around the blade to block airflow, with different iterations consisting of variable shells, materials, and shapes. The blocking method we have developed for this blade can be adapted and applied to all Pratt & Whitney turbine blades.