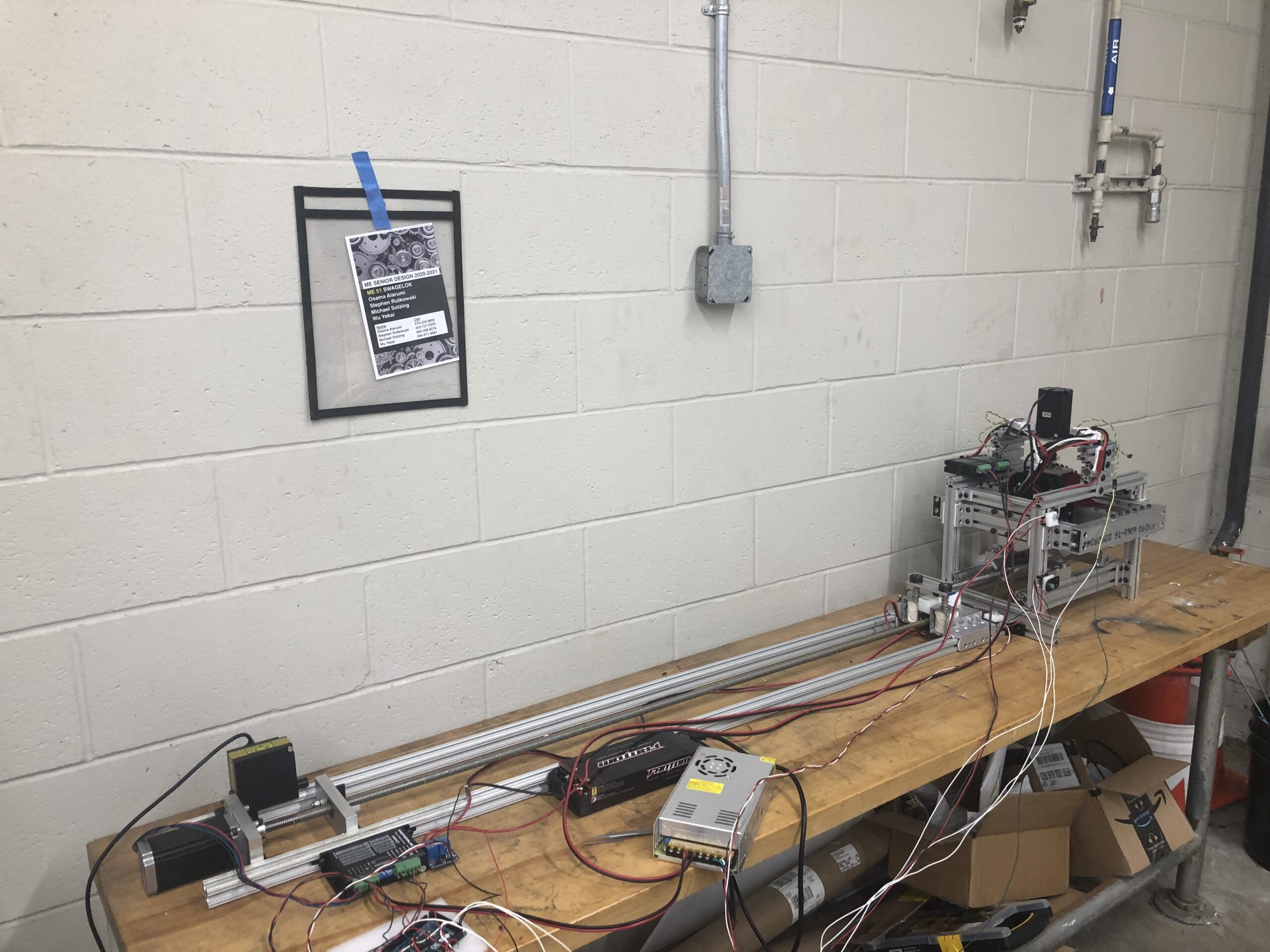

Figure 1

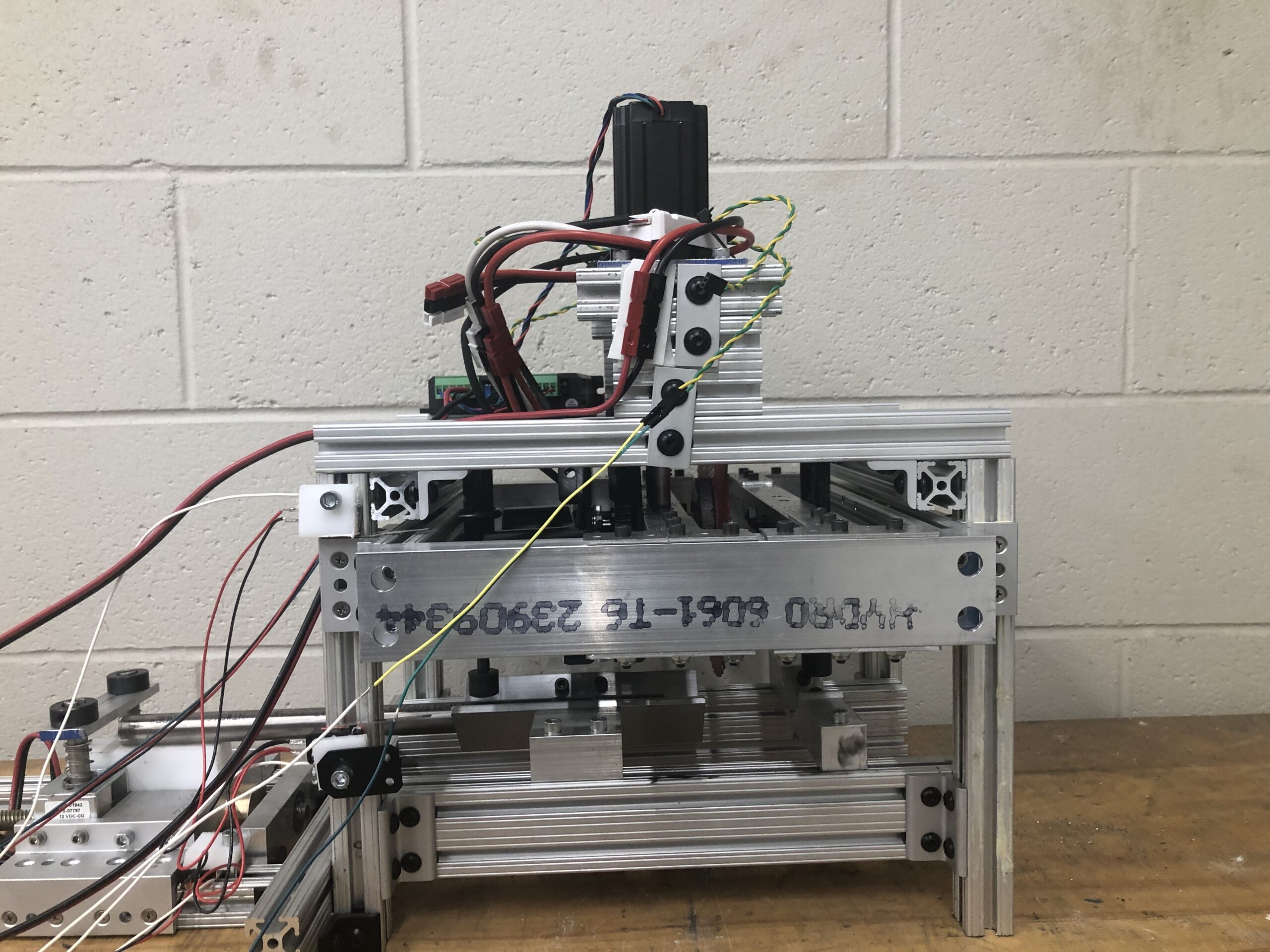

Figure 2

Team 51

Team Members |

Faculty Advisor |

Osama Alarumi |

Thomas Mealy Sponsor Swagelok |

sponsored by

Swagelok is a private international company that specializes in tube manufacturing for gas and fluid system components. They provide components that are made to order and prepare to meet any of the various parameters that customers may request. The objective of this project is to design and build a fully automated tube cutter that can handle and be preset to make differently sized cuts from 20 feet, 316 stainless steel tubes, and must comply with several requirements. This tube cutting machine would be a critical integration to Swagelok’s efficiency for future endeavors. A specified criterion is the size range of the tubes it will be fed; this machine must allow cuts up to 4 feet, and for tubes with an outside diameter range of ¼” to ¾”, and a wall thickness range of 0.035” - 0.095” cuts. It must also support holding and being fed ten of these tubes at once, and must withstand over 100 cuts consecutively without the need for maintenance. The most critical parameter is that this machine must be able to perform cuts that require minimal post processing and no discoloration of the tubes, as that will cause the product unusable. The machine is designed to take these sticks of tubing, feed them into the conveyor which then puts the tube under the saw blade at the preset desired length, and performs the cut.