Figure 1

Figure 2

Team 63

Team Members |

Faculty Advisor |

Nicholas Erskine |

Baki Cetegen Sponsor Other |

sponsored by

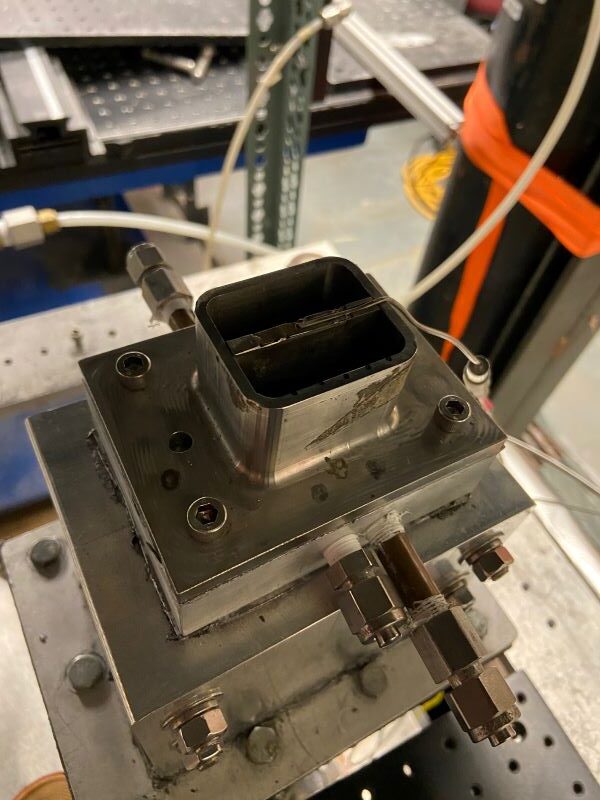

The purpose of this Senior Design Project is to prepare a bluff-body combustion rig for liquid fuel that is to be pre-mixed with heated air. The fuel injection system is updated to reliably measure and control the fuel’s flow rate using a variable area flow meter. Thermocouples, silicone rubber heating tapes, and a temperature controller are implemented to monitor and heat the walls of the combustion rig to prevent fuel droplet condensation. This is meant to completely vaporize the fuel droplets to maximize mixing between the fuel and air molecules before reaching the bluff-body-stabilized flame. The flames of interest in this research are stabilized on a piece that spans across the long-side of the rectangular cross-section where the premixed fuel-air flow exits. This is known as the bluff-body. It is of interest to analyze flames where the average fuel-air velocity is 5, 10 and 15 m/s at the bluff-body. Since the air that comes from a compressor is the bulk of the mass flow, Hot Wire Anemometry (HWA) is conducted to calibrate the compressor air pressure to the velocity at the bluff-body. The fuel droplet vaporization is tested using a Particle Image Velocimetry (PIV) laser and camera that detects scatter from larger particles, such as fuel droplets, in a flow of gas. Beyond the Senior Design timeline, the goal of this research is to investigate flame behavior as flames of jet fuel components (n-dodecane, toluene and ethanol) near blowoff. Flame characteristics such as temperature, velocity, flame shape, flame height, and species composition, can be measured using advanced laser diagnostic techniques. The measuring techniques used in this project include Filtered Rayleigh Scattering (FRS), PIV and High Speed Chemiluminescence Imaging. FRS and PIV are used to obtain temperature and velocity data of the flame and its surrounding area. This data can then be compared between flame stages as a flame nears blowoff to observe how a flame’s behavior changes.