This video contains proprietary information and cannot be shared publicly at this time.

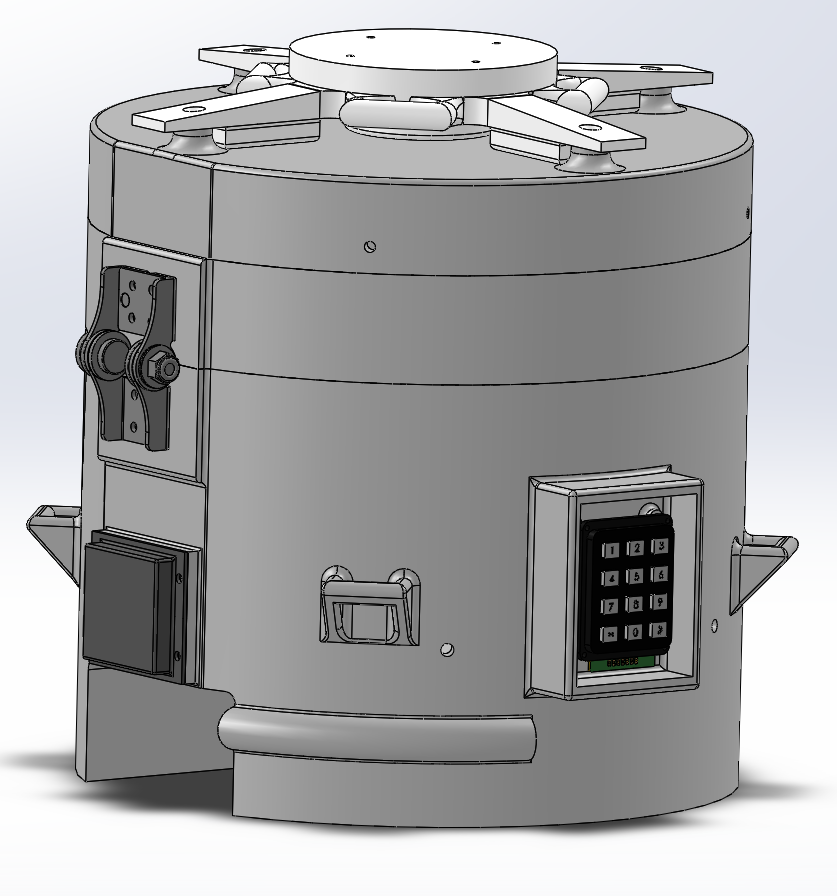

Figure 1

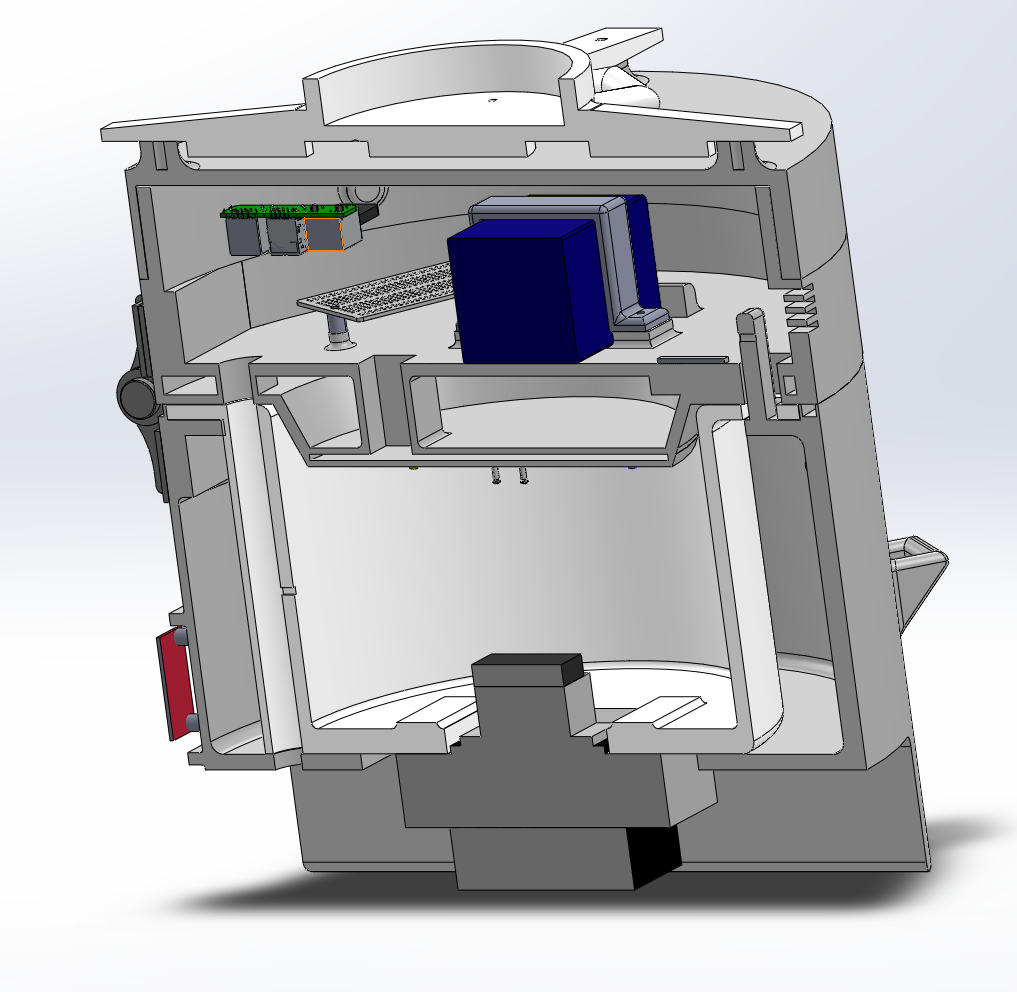

Figure 2

Team 07

Team Members |

Faculty Advisor |

Brian Frechette |

Professor Chengyu Cao Sponsor Aquiline Drones |

sponsored by

Aquiline Drones provides Unmanned Aerial Vehicle (UAV) solutions for various applications across several industries. Several patients are unable to receive critical medication and/or vital organs needed for transplants in a timely manner due to issues surrounding logistics and unreliable delivery. The new Smart Box concept seeks to improve the likelihood that a patient receives such critical materials promptly by providing a UAV solution catered to the efficient transport of temperature sensitive materials. The objective of this project is to design, fabricate, and test a box concept that will optimize the delivery of temperature sensitive medicines and biological specimens, including human organs and tissue. This is a joint project between Mechanical Engineering (ME) and Electrical Engineering (EE). Major constraints with regards to the ME team include the aerodynamic form of the box, carrying capacity, impact resistance due to drops, box weight and dimensions, exterior UV rated material, internal insulating and biocompatible material, and an interior cooling system. It was desirable to 3D print our box, so we decided on using Acrylonitrile Styrene Acrylate (ASA) for our external shell and acrylonitrile butadiene styrene (ABS) for an internal box. Expanding Polyurethane was selected as the best insulating material due to its impressive 6.7 R-value. Thermoelectric cooling via a Peltier device was selected due to its compact structure, low weight, low cost, and effective cooling, as it proved capable of maintaining a target temperature of 8 degrees celsius during testing. The Peltier device operates in conjunction with a relay switch, enabling the system to be powered on or off depending on current system temperature requirements. The model was designed in Solidworks and iteratively tested in ANSYS using impact and vibration simulations. The box is set to be 3D printed and assembled throughout the month of April for a final demo at Aquiline Drones.