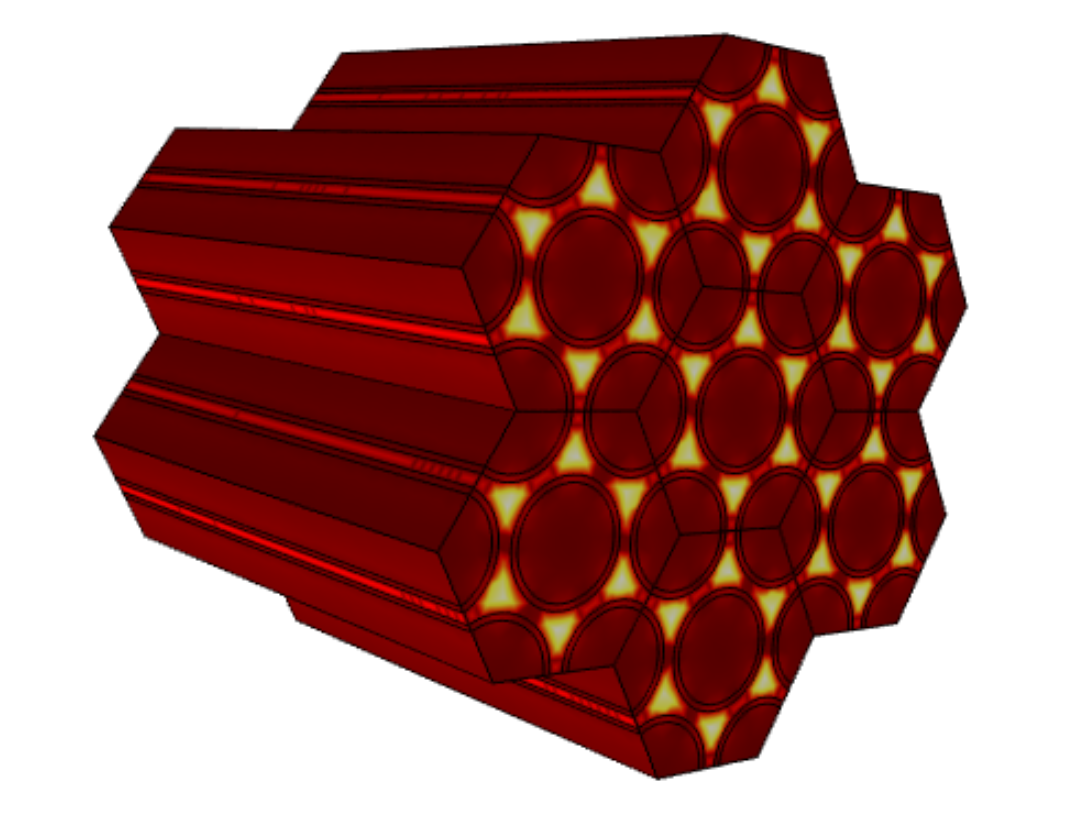

Figure 1

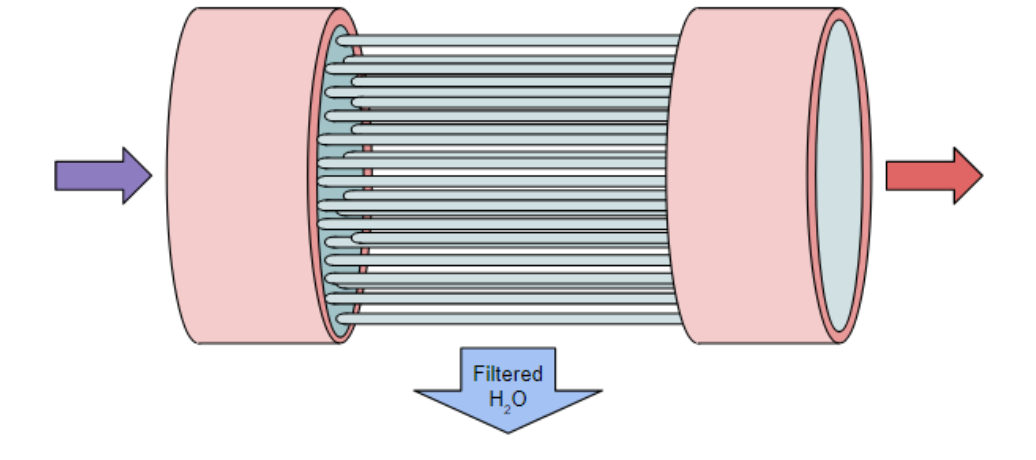

Figure 2

Team 11

Team Members |

Faculty Advisor |

Rachel Boislard |

Dr. Mu-Ping Nieh Sponsor Other |

sponsored by

Designing Epoxy Potting of Caps for Capillary Filtration

Over one billion people face water scarcity globally, and this number is only increasing as humanity’s population grows. One solution to this issue is to develop smaller, more efficient water filtration systems that filter and sanitize non-potable water. Our project focuses on refining the design for the epoxy setting within capillary filtration devices. Capillary water filters consist of bundles of thin, hollow, glass fibers potted in epoxy caps to ensure that the fibers stay bundled together as water passes through the filter. To create these caps, technicians pour the liquid epoxy over the fibers and allow it to harden. This process, known as curing, releases heat that can damage the capillary fibers and render the filtration system inoperative. Our project focuses on modeling the heat released from the epoxy curing process and developing a solution to control this heat so that the capillary fibers remain intact. We used COMSOL to model the three-dimensional geometry of the filter and to vary three parameters: the initial temperature of the filter prior to potting, the material of the capillary fibers, and the porosity of the epoxy. The resulting model optimizes the time it takes for the epoxy to fully cure and reduces the heat generated by the reaction. Ultimately, this model has the potential to improve the manufacturing of water filtration systems and expand access to safe drinking water across the globe.

Our team collaborated with on this project.