Figure 1

Figure 2

Team 2

Team Members |

Faculty Advisor |

Carmine Muratore |

Ryan Cooper Sponsor Aerogear |

sponsored by

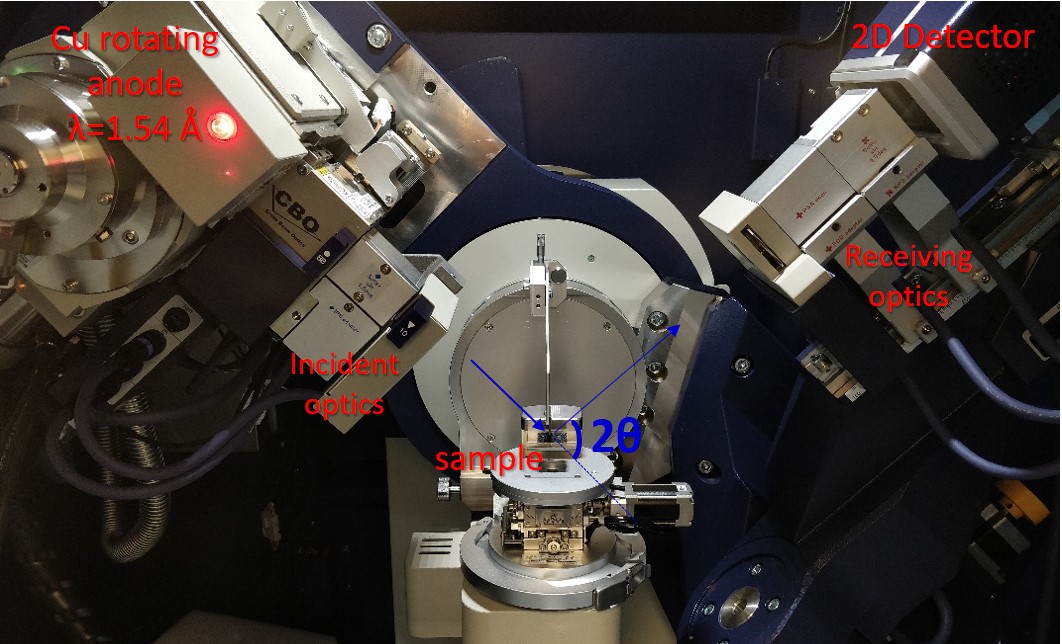

Gear Residual Stress Measurement

The durability of gears is strongly influenced by surface residual stresses which are dependent on a variety of factors, one of these factors is the gear grinding process. For this project ME02 will work with Aero Gear to measure and develop a relationship between grinding and residual stress on a representative gear tooth geometry. Aero Gear is based in Windsor, CT and produces aerospace precision gears and gearbox assemblies. Gear grinding has several parameters that can affect residual stresses. The parameters that the team will be testing are material removal rate, grinding wheel roughness, and grinding wheel composition. To measure the residual stresses within the gear the team will be working with the material science engineering department using X-ray diffraction. X-ray diffraction works by emitting X-rays at the material and measuring the diffraction angle. From this angle the spacing between the crystal lattices can be determined and from there, residual stress.