This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

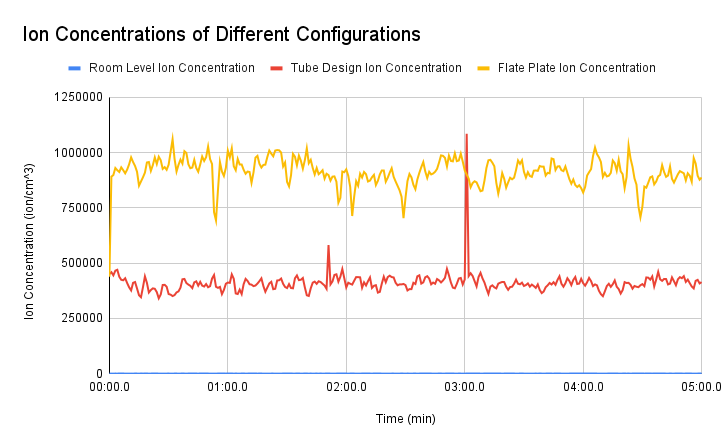

Figure 2

Team 10

Team Members |

Faculty Advisor |

Michael Calvert |

Vito Moreno Sponsor Other |

sponsored by

Substrate material for Flat Plate Bi-Polar Ionization

AtmosAir Solutions is an air purification system manufacturer that strives to improve air quality in all types of indoor settings. They currently use a plasma generating tube design to conduct the bipolar ionization process, but they are looking to improve their units with the all new flat plate design. Our goal was to determine a dielectric material that will efficiently conduct bipolar ionization for a longer period of time. We tested each of these materials on their ability to conduct ions and their thermal durability. The ion production test used a 110 CFM reference fan blowing through a 3’ pipe with a 6’’ diameter and collected data on the amount of negative ions per cubic centimeter through the ASCI-II ion meter. In order to determine which material best contributed to ion production, we combined identical anodic and cathodic components to each dielectric forming test pieces. These test pieces were placed into our test rig and run for 5 min after a warm-up period for a total of three times to best collect the average ion production. The thermal durability test determined which material would best handle the high temperatures of bipolar ionization. The material should function for two or more years in temperatures between 750°F-1500°F. To achieve similar thermal stresses, we used an aggressive approach of cyclically heating and cooling the materials 50-100 times to observe any material changes. Our testing will give AtmosAir information on which material will allow them to produce efficient flat plate ionization devices.