Figure 1

Team 25

Team Members |

Faculty Advisor |

Justin Boissonneault |

Bryan Weber Sponsor Other |

sponsored by

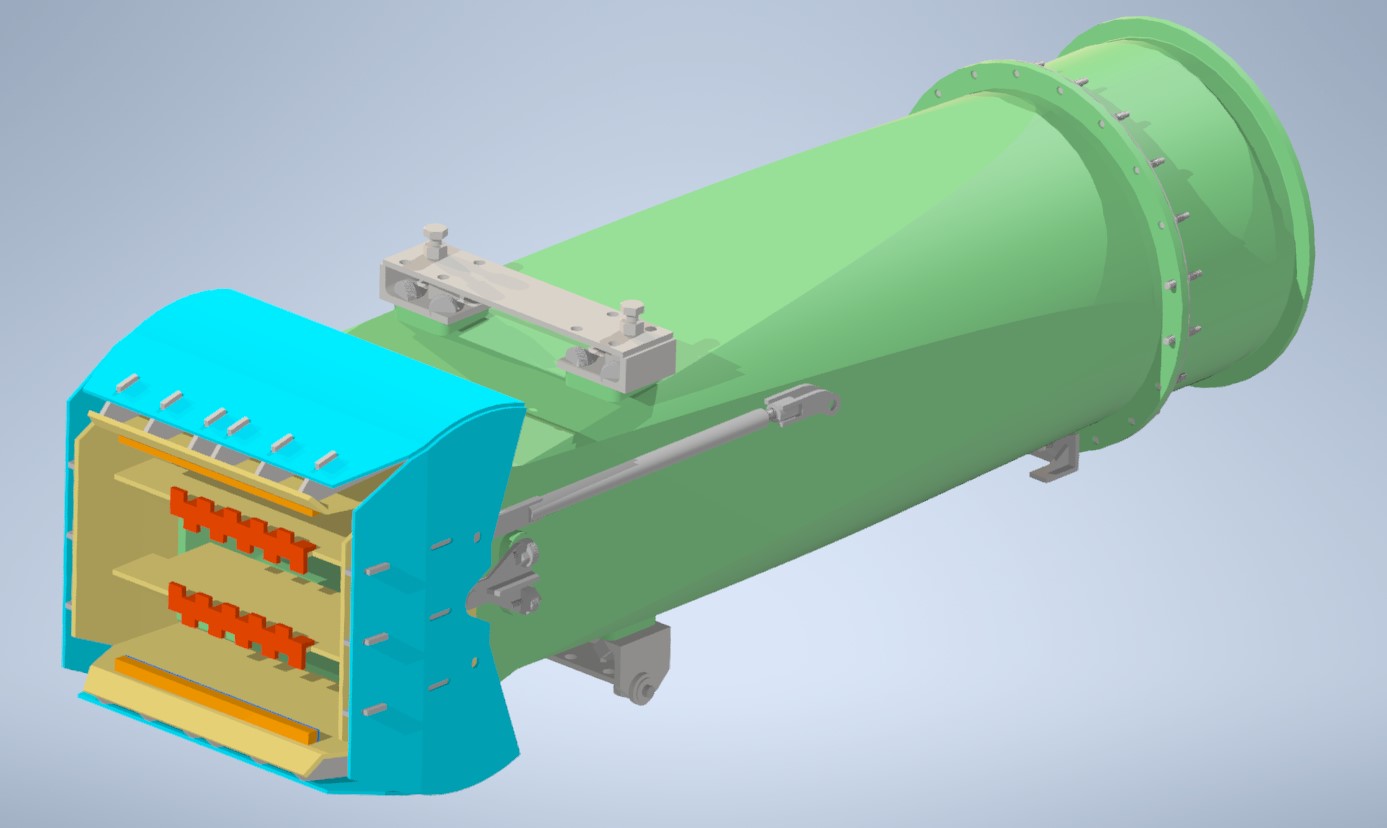

Coal Nozzle Tip - Increase Operational Life

This project was focused around extending the operational life of a coal nozzle tip of a commercial sized power generation plant. General Electric has tasked us with identifying and eliminating warpage in the external wrapper plate caused by extreme temperatures. The nozzle is responsible for delivering two separate streams, fuel (coal) and combustion air to the furnace. The current operational life of this part is 2-3 years and then requires replacement per request of the consumer. A static temperature analysis yielded an incredible temperature gradient of the plate and was deemed the source of the problem. Through further evaluation using ANSYS Fluent we created multiple design variations utilizing the combustion air flow to reduce the temperature gradient.. The current design is strictly a smooth flat plate with no interior or exterior features to modify the flow of the secondary air stream. The redesigned plates feature drilled holes through the plate at various angles. The goal of the drilled holes is to create vacuum sucking the external stagnant air in the furnace chamber into the nozzle and heat the inside boundary of the wrapper plate. In increasing the temperature on the interior of the plate we can reduce the overall gradient and keep the plate at a more uniform temperature reducing the probability of warpage.