Figure 1

Figure 2

Team 44

Team Members |

Faculty Advisor |

Pujan Patadia |

Vito Moreno Sponsor Pratt & Whitney |

sponsored by

Material and Structural Response Under Dynamic Loading

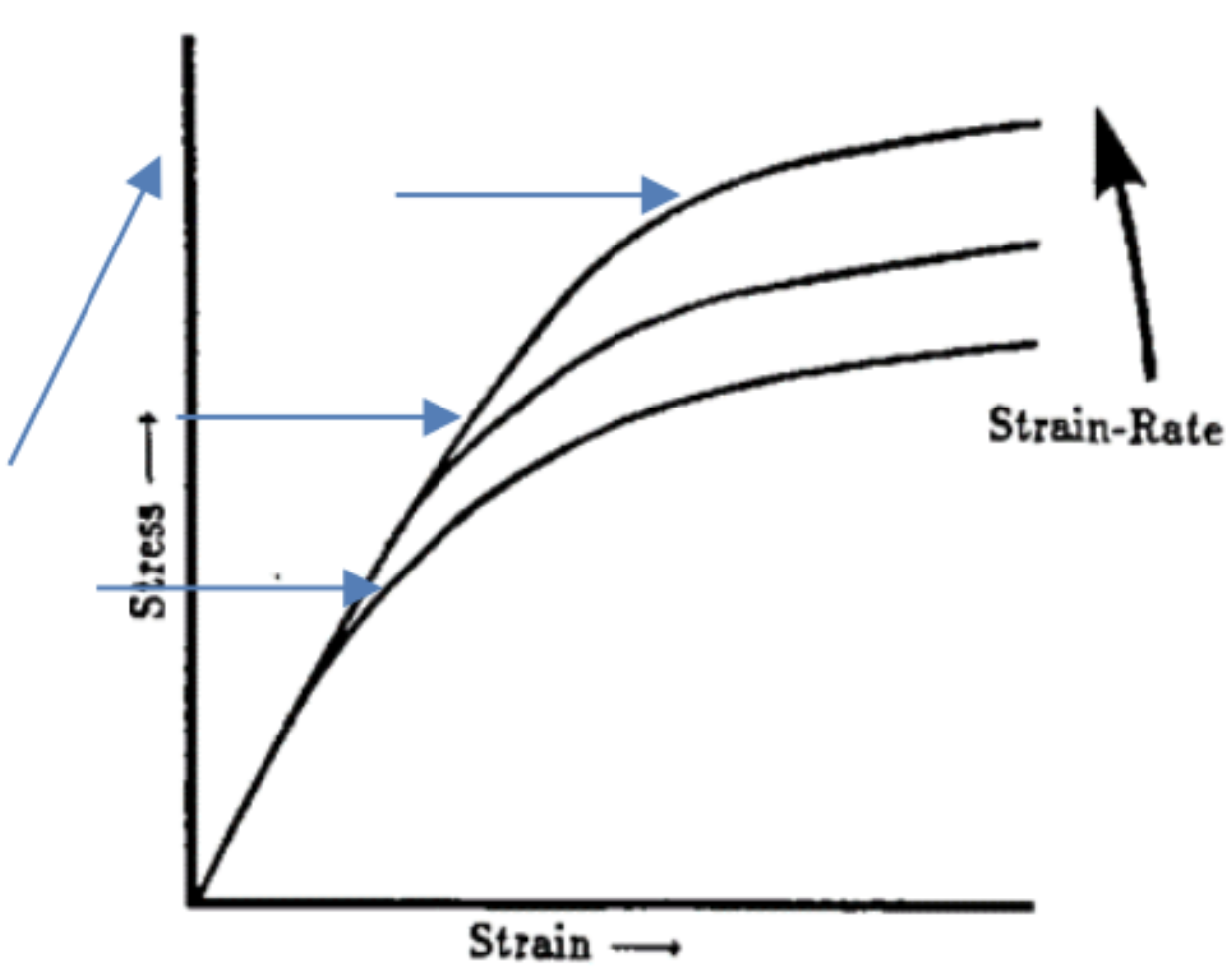

The objective of this project is to run tensile tests on aluminum alloys that used as structural components of turbine engines at varying strain rates to understand the relationship between strain rates and mechanical properties. During flight, gas turbine engines are subjected to mechanical stresses. In certain situations fan blade failure can occur, where the fan blade will break off, causing the turbine to be subjected to large impact loads. Fan blade out is a highly dynamic and transient event with complex loading and system-level effects. During this event, deformation will occur to the structural components of the turbine with very high strain rates. When metals deform with a very high strain rate, it is known that their mechanical properties, such as ultimate tensile strength and ductility, increase. Currently, in the aerospace industry, the mechanical design of turbine supporting structures is done by using data obtained from tensile tests using a static, or very low, strain rate. We are tasked to quantify and understand the difference in strain behavior of a material and component loaded with the same magnitude of force but varying the time under loading. The preferred material to be tested is a low ductility aluminum alloy because of its common use in aerospace applications.

Our team collaborated with Materials Science & Engineering 5 on this project.