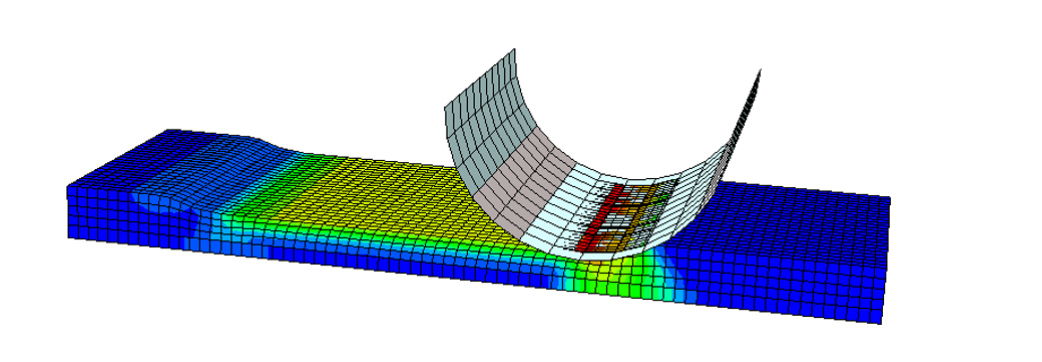

Figure 1

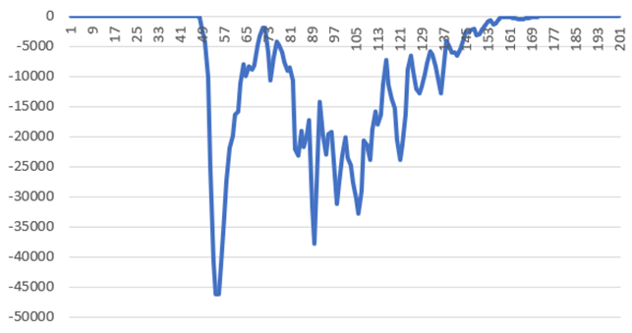

Figure 2

Team 67

Team Members |

Faculty Advisor |

William Hobson-Rhoades |

Hongyi Xu Sponsor NIUVT |

sponsored by

Simulating the Lithium-Ion Battery Electrode Calendaring Process

In this project, several simulations needed to be created in order to best simulate the battery electrode calendaring simulation. The first of these is a macroscopic simulation, which is used to determine large-scale properties of the electrode, such as general density distribution before and after the calendaring process. In this simulation, a roller is dropped onto the battery electrode, and then horizontally translated across the surface. Next, a macroscale simulation needed to be created to determine the material properties of the macroscale simulation. This simulation was created by distributing different numbers of particles throughout a cube, and translating one side of the cube inward, in order to compress the particles. This deformation provided a stress-strain curve, which would be applied to the macroscopic model. The other component of the microscale model was to determine the electrochemical properties of the battery. The three analyzed properties were tortuosity, effective conductivity, and active surface area. They could be determined from the model by replicating the morphology of the battery electrode. This model was created by filling x-ray images of the battery electrode with particle centers, and expanding the particles to best fill the material parts of the image. The remaining material parts were filled with particles with properties of binder, replicating the structure of the electrode. These properties could then be used to determine the battery’s performance.