This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

Team 4

Team Members |

Faculty Advisor |

Mark Caiafa |

Burcu Beykal Sponsor Other |

sponsored by

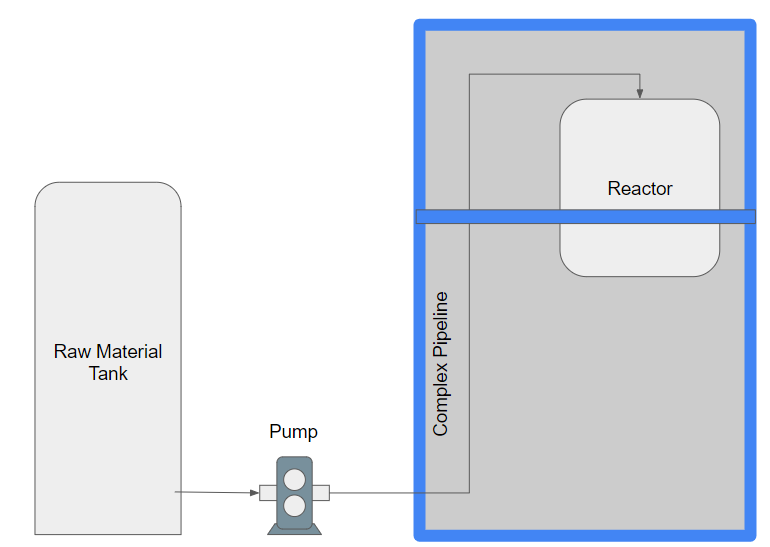

Engineering for Efficiency: A Redesign of BYK USA's Raw Material Pumping Systems

BYK USA is a leading global supplier of specialty chemicals. They produce 150 different additives at their regional headquarters in Wallingford, CT. Starting from over 350 different raw materials, the plant provides products used across a wide variety of industrial applications including paints, plastics, pharmaceuticals, food, and lumber. In recent years, BYK USA has experienced a massive soar in demand and is running 133% above their present process throughput specifications. While they are undergoing a plant expansion, their current operating pumps and piping systems are not optimized for their latest recipes. This has created production bottlenecks. We re-designed the raw material transfer pumps to allow process throughput gain opportunities. Applying chemical engineering fundamentals, we analyzed the design basis of the existing pumps and upsized accordingly to increase material transfer times from the outdoor storage tanks to unit operations in the plant. Additionally, we calculated the net present value (NPV) of the newly designed pumps to prove their economic viability and determine their total added value. Factored in our design are important environmental and safety considerations limiting pump size such as maximizing energy efficiency and preventing runaway reactions. Our team’s final design has increased BYK’s capacity to produce high-quality chemicals as they expand to meet growing industry demand.