This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Team 10

Team Members |

Faculty Advisor |

Ramisa Hossain |

Francisco Cunha and Craig Calvert Sponsor Belimo Americas |

sponsored by

Identification and Transportation of Non-Value Added Materials Using AMR Technology to Improve Utilization of Labor Hours

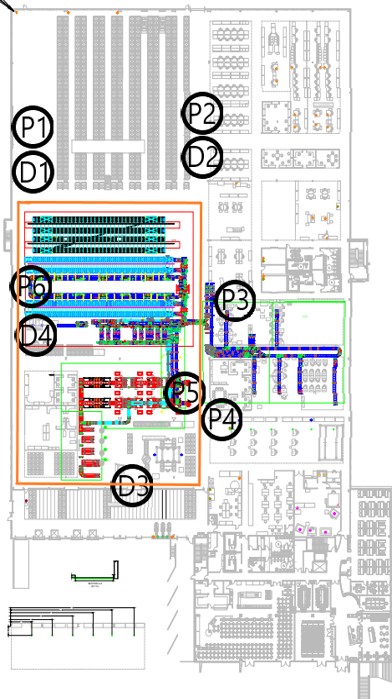

Belimo, a renowned global leader in the HVAC industry, prides itself on its operational efficiency. The company has gained a competitive advantage by offering short lead times, which are made possible by its advanced automation processes at multiple manufacturing locations. In order to maintain this edge, it is imperative to continue optimizing the efficiency of its processes. The next step in this endeavor is to automate the transportation of non-value adding materials. The current manual transport system requires workers to move away from their workstations, causing production delays. The implementation of Autonomous Mobile Robots (AMR) technology will enable the automated transport of such materials, allowing workers to remain focused on their tasks and increasing overall productivity. Throughout this project, we conducted extensive research on various AMR vendors and identified the MiR 600 as the best fit for Belimo's specific needs and capabilities. We also mapped out the optimal pickup and drop-off points to ensure efficient transportation routes. After conducting a thorough analysis of transportation frequency and speed, we have determined that only 0.4 AMRs are required to facilitate all material transports at Belimo. This finding has significant cost-saving implications, as it minimizes the need for excessive investment in unnecessary AMRs. Our technical specification document, which details the system requirements and installation guidelines, will be included with the purchase order to ensure that Belimo can seamlessly integrate the AMR technology into their manufacturing process for future projects. By implementing the MiR 600 AMR system and optimizing the transportation routes, Belimo will be able to maintain its competitive edge and continue to provide customers with short lead times and unparalleled efficiency.

Our team collaborated with Mechanical Engineering 11 on this project.