This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Team 05

Team Members |

Faculty Advisor |

Jared Augeri |

Craig Calvert and Francisco Cunha Sponsor Other |

sponsored by

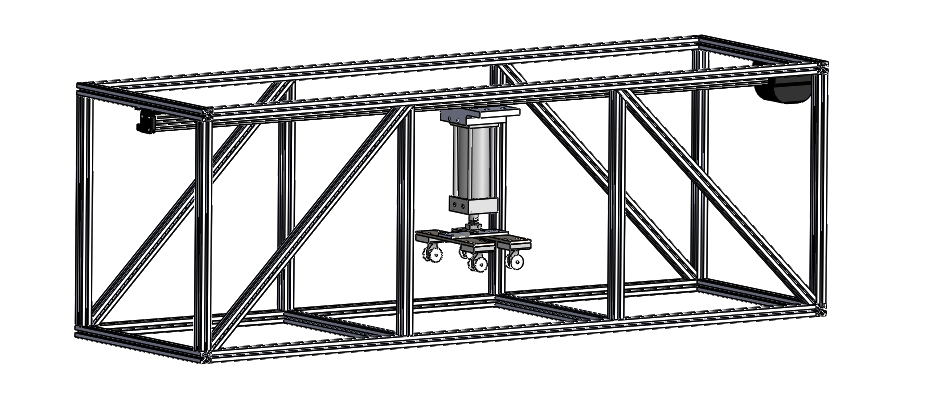

Machine Design for Faster O-Ring Installation to Meet Current and Expanding Retailer Demand

i2Systems is an industry leader in LED lighting technology, product design, and manufacturing. With a vertically integrated approach to manufacturing, they are able to provide top performance, reliability, and flexibility. i2Systems is proud to assemble their products in-house in Morris, CT. The company has taken on a contract with a large retailer and is exploring manufacturing automation to replace the manual installation process of o-ring cords into light fixtures. The tedious, repetitive, and tiring manual process takes a toll on the well being of assemblers. As a result, it can prolong the cycle time and decrease quality. The proposed solution eliminates ergonomic concerns and decreases cycle time by creating a machine that moves linearly while also applying pressure. Within the construction of the aluminum extrusion frame, the linear actuator and pneumatic system work together to roll the o-rings into crevices of the light fixture. This design allows for two light fixtures to be rolled in simultaneously which cuts cycle time and allows assemblers to perform other value adding tasks. In turn, this will allow i2Systems to remain a leader in their industry by increasing their capacity so that they can take on other clients.