This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

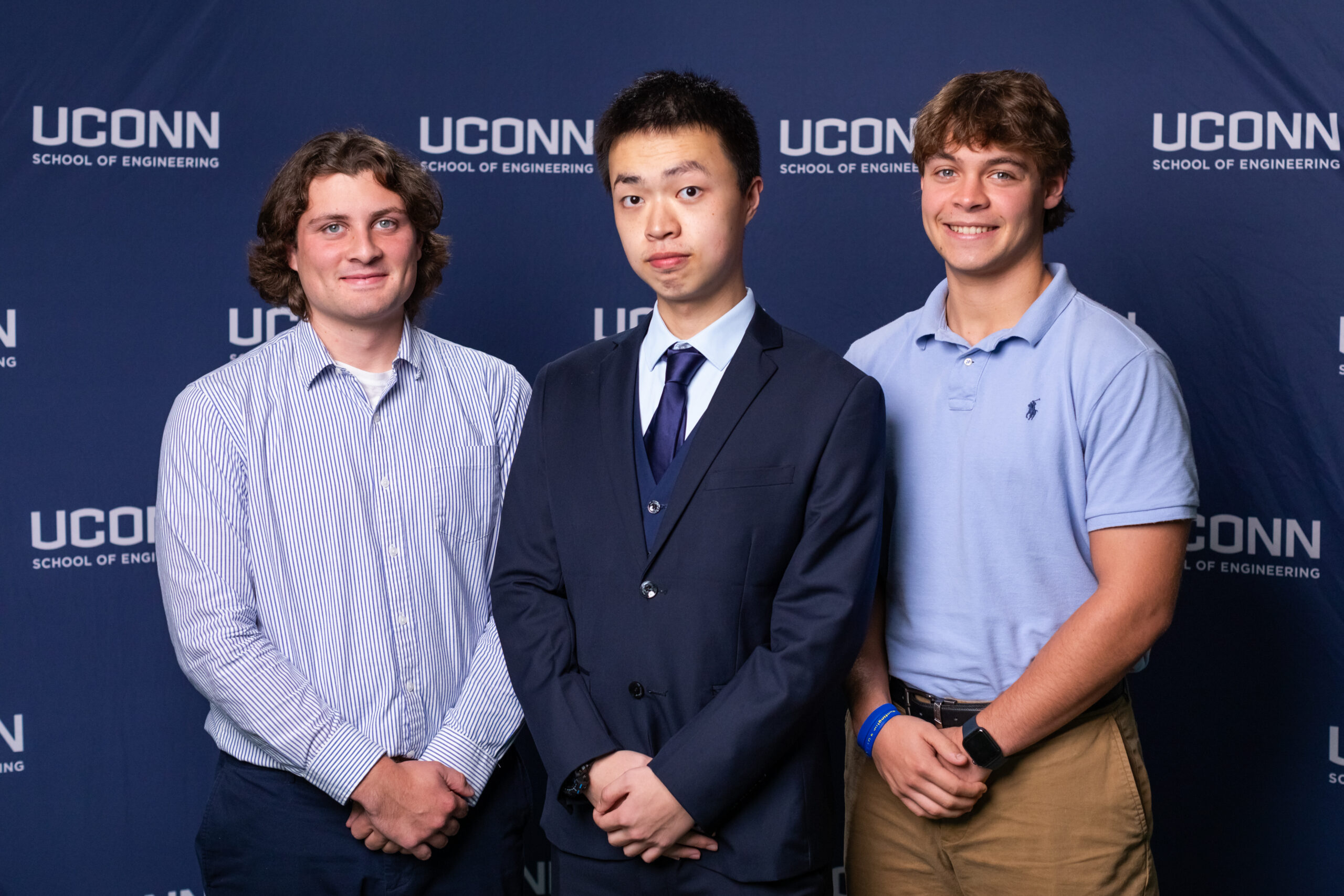

Team 40

Team Members |

Faculty Advisor |

Brendon Trask |

David Giblin Sponsor Pratt & Whitney |

sponsored by

Hybrid Composite Metal Case Design

Pratt & Whitney (P&W) strives for designing and manufacturing dependable long-lasting engines in both military and commercial industries. Sustainable engines are the future for lowering emissions, and Pratt & Whitney’s commercial GTF (Geared Turbo-Fan) engine program strives for peak efficiency in every engine they make. The addition of gears in new engines allows for high-pressure turbines to spin at different speeds than the low-pressure turbines, allowing each turbine to operate at optimal RPMs at cruising speeds. The gears add significant weight to the engine despite driving a higher efficiency. Pratt & Whitney looks to lower the weight in other areas of the engine, one focus is the implementation of composites. A downfall of composites is their integrity when implemented with fasteners, our goal is to explore flange designs that can optimize and strengthen metal flange-to-composite case interfacing. Our sponsors, Connor Perry and David Lussier strive to deliver high-efficiency engines at lower weights by nearly halving the weight of traditional all-metal fan cases by integrating composites safely and ensuring integrity of flange connections. This project aims to test various axial flange arrangements found on engine fan cases through tensile tests on composite materials fastened to traditional metal components. Originating from Pratt & Whitney's goal to reduce engine weight, the project builds on the 2022-2023 ME 46 Senior Design team's findings on circumferential flange joints, extending the investigation to axial flange configurations. The challenge lies in designing and fabricating test panels based on a simple 2-D axial flange arrangement design provided by P&W.

Our team collaborated with Materials Science & Engineering 6 on this project.